Further Rotor / Beater Mills

FURTHER PRODUCT GROUPS

Variable Speed Rotor Mill

PULVERISETTE 14

premium line-

OVERVIEW

Fast pre- and fine-grinding in one instrument

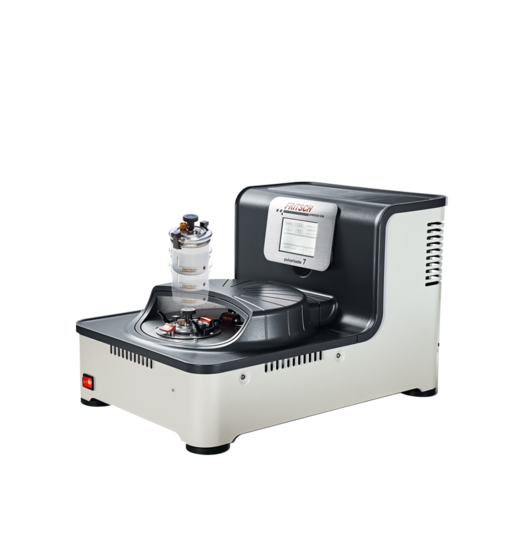

The FRITSCH Variable Speed Rotor Mill PULVERISETTE 14 premium line offers impact, shearing and cutting comminution in one instrument – with a higher performance, better cooling and is significantly quieter than comparable instruments. Its powerful motor is ideal for the particularly fast comminution of soft to medium-hard, brittle as well as fibrous materials and temperature-sensitive samples with an extremely fast sample throughput, which can be further increased by the use of the FRITSCH Cyclone separators.

Due to its high performance, the PULVERISETTE 14 premium line is the ideal Variable Speed Rotor Mill for comminution at pilot plant-scale in the plastics industry.Two Mills in one instrument: With the cutting rotor you turn the PULVERISETTE 14 premium line into a Cutting Mill for fast, efficient pre- and fine comminution of soft to hard-tough, fibrous materials and plastics.

-

WORKING PRINCIPLE

Impact, shearing and cutting comminution

Inside the Variable Speed Rotor Mill, the sample is comminuted by impacting against the ribs of the impact rotor, rotating at high speed and also sheared between the rotor teeth and the inserted sieve ring.

When using the mill as a Cutting Mill, comminution takes place by cutting and shearing between the cutting rotor and the fixed knives of the sieve shells holder. -

FEATURES

- Powerful grinding with 22,000 rpm for particularly fast sample throughput

- Extremely high impact speed of the impact rotor (111 m/s = 399.6 km/h)

- Max. feed size < 15 mm, sample throughput of up to 15 l/h and more

- Final fineness d50 < 40 μm, sieve rings 0.08 – 6 mm

- Multifunctional with impact or cutting rotor in one instrument

- Samples which are difficult to grind or extremely temperature-sensitive can be embrittled with the addition of liquid nitrogen and subsequently ground

- Intelligence-Safety-Control-System for particularly safe operation

- Batchwise or continuous grinding with FRITSCH Cyclone separators- Particularly good cooling of the grinding material due to extremely high airflow

- Easy cleaning due to Clean Design

- Removable dust filter for convenient cleaning

- Wear-free labyrinth seal between the grinding chamber and drive motor

- Quiet operation according to DIN EN - Flexible remote control

- USB interface as well as integrated regulation for the Vibratory Feeder LABORETTE 24

- Grinding chamber made of stainless steel 303 resp. 316L PTFE coated

- Grinding parts made of stainless steel 431 resp. 316L, pure titanium, hardmetal tungsten carbide or zirconium oxide

-

Cutting with the Pulverisette 14 premium line

Unique double use as Cutting Mill

Only available from FRITSCH: The PULVERISETTE 14 premium line is the only Variable Speed Rotor Mill on the market, which is also suitable for cutting. As a Cutting Mill it is ideal for fast, efficient pre- and fine comminution of soft to hard-tough, fibrous materials and plastics with a max. feed size < 10 mm.

Easy conversion: Simply insert a labyrinth disk, a collecting vessel, a cutting rotor with cooling fins, a sieve shells holder with fixed knives and sieve shells as well as the lid of the collecting vessel. The comminution then takes place by cutting and shearing. The instrument detects the inserted labyrinth disk and automatically operates optimised up to 18,000 rpm and a cutting rotor peripheral speed of up to 83 m/s for extremely high final finenesses. Cutting rotors, fixed knives and sieve shells made of different materials can be used for controlling the abrasion behaviour – for each application the perfect solution. The selected sieve shells, which are offered with trapezoidal or round perforation from 0.08 – 4 mm, determine the desired final fineness. And the use of a FRITSCH Cyclone separator will further improve throughput and cooling and is indispensable for finer mesh sizes.

Especially convenient: In contrast to conventional Cutting Mills, the entire grinding chamber of the PULVERISETTE 14 premium line – not only the cutting rotor and sieve insert, but also the collecting vessel with lid and fixed knives – can be removed and cleaned in the dishwasher. And for sterile comminution, all grinding parts, which come into contact with the sample and the grinding chamber itself, are autoclavable.

-

premium-functionality for flexible operation

Intelligent control

The Intelligence-Safety-Control-System automatically checks the components of the grinding set – labyrinth disk for impact or cutting rotor, collecting vessel with lid – for completeness and correct insertion. Even the FRITSCH Vibratory Feeder LABORETTE 24 is detected by the programme. The grinding starts only when all the parts are fully and correctly inserted and the instruments lid is properly locked.

Absolutely safe

If the instrument lid with the practical quick-clamping lock is opened unintentionally, an integrated safety lock prevents the opening of the instrument.

Display of grinding parameters

Operation is done via the ergonomically arranged touchscreen with intuitive menu structure in different languages. Enter the variable rotational speed and define the grinding time in minutes and seconds. A stopwatch function facilitates the time recording e.g. for new samples. The display of power consumption and system temperature ensures easy control, and a warning is shown in case of overload and overheating.

Flexible remote control

If your PULVERISETTE 14 premium line is isolated for special grinding tasks – e. g. in a glove box – it can be easily remote controlled using a separate computer. All system values can be read directly as well.

High-speed motor with ceramic bearings

The heavy-duty motor and especially durable ceramic bearings ensure a particularly high impact and rotor speed with extra powerful 22,000 rpm and finer results in shorter times.

-

SIGNIFICANTLY BETTER COOLING

Strong cooling

The strong airflow produced by the motor, an ingenious air routing, as well as special cooling fins on the rotors further intensify cooling. Melting or sticking is greatly reduced, even with temperature-sensitive samples. The motor airflow can be further enhanced by the option to connect an exhaust system and the cooling effect of the sample can be additionally increased by using a FRITSCH Cyclone separator.

In the PULVERISETTE 14 premium line, the grinding and electrical chambers are completely separated from each other. Your advantage: The air in the grinding chamber does not come into contact with the electronics and stays cooler – and the electronics are protected from dust. A clever idea, which results in a longer service life for your mill and increased safety with no faulty circuits.

-

CLEAN DESIGN

For fast cleaning

The well-conceived Clean Design of the Variable Speed Rotor Mill PULVERISETTE 14 premium line covers all the areas, which make the cleaning of your mill as easy as possible: All the surfaces are designed to be extremely dirt-resistant and easy to clean. Every surface which comes into contact with the samples can be sterilised.

And all the parts that need regular cleaning – funnel, collecting vessel with lid, rotor, sieve ring/sieve shells holder and labyrinth disk – each can be removed with a single motion without tools and can be cleaned in the ultrasonic bath or in the dishwasher. The innovative laser welding of the sieve rings enables due to less dead spaces a significantly easier cleaning, as well as greater stability and longer service life. -

FRITSCH CYCLONES

Temperature gentle fine grinding with the FRITSCH Cyclones separators

Regardless of whether you use the instrument as Variable Speed Rotor Mill or Cutting Mill: only the combination with a FRITSCH Cyclone separator and exhaust system for sample exhaustion delivers the optimum result.Your advantages with a FRITSCH Cyclone separator:

- Faster throughput- Improved discharge of material from the grinding chamber

- Additional strong cooling of the grinding material and grinding parts

- Efficient size reduction of temperature-sensitive samples, electrostatically charged plastics or powder coatings

- Ideal for light materials, small sample quantities and finer sieve sizes

- Highly efficient continuous comminution of large quantitiesWe offer two models matching your specific applications:

FRITSCH high-performance Cyclone separator: : The FRITSCH high-performance Cyclone separator completely made of stainless steel 304 is particularly indispensable in the analytical sector and in the food and pharmaceutical industries. Due to its high surface quality, it offers enhanced resistance to corrosive media such as alkalis and acids and is especially easy to clean with a wide range of possible cleaning agents, without leaving any residues. In addition, it can be completely dismantled, fully emptied, flooded and sterilised. Your advantage: reliable protection against cross-contamination.

FRITSCH small volume Cyclone separator: The compact FRITSCH small volume Cyclone separator made of plastic with sample glass 250 ml or 500 ml is particularly suitable due to its material properties for heavy-metal- and iron-free grinding and sample preparation according to RoHS with impact and cutting rotor. In addition, it offers all advantages of the FRITSCH Cyclone separators for the size-reduction of small quantities. It guarantees absolute safety against contamination and can be completely dismounted and cleaned in a dishwasher. The small volume Cyclone separator should be combined with an exhaust system, which can be ordered along. With the provided fine-dust filter 80 – 100 μm, the small volume Cyclone separator can also be used passive for dry, free flowing samples in small quantities up to 200 ml, such as rice or maize kernels and when using medium sieve sizes.

-

EQUIPMENT / ACCESSORIES

Configure your Variable Speed Rotor Mill PULVERISETTE 14 premium line exactly to your specific application

The Variable Speed Rotor Mill PULVERISETTE 14 premium line is equipped with a funnel made of polyamide and stainless steel 316L and funnel lid. Order according to your task the suitable collecting vessel with lid and labyrinth disk, impact resp. cutting rotor, sieve ring resp. sieve shells. This is the basic equipment needed for utilising the Variable Speed Rotor Mill or Cutting Mill.

Directly controlled by and precisely matched to the mill, the FRITSCH Vibratory Feeder LABORETTE 24 always ensures the correct feed rate – ideal for the slow feeding of small or smallest material quantities or for grinding larger quantities. An IQ/OQ documentation is available to support equipment qualification.

-

Applications / Solutions

-

When it comes to 3D printing, the principle from the large to the small is reversed. In previous, well-known manufacturing processes, a component is created by removing material, for example by means of CNC turning or milling. In additive manufacturing, the approach is virtually reversed. Here, the part previously designed in CAD is created from a powder or a liquid by means of a 3D printing process.

-

Comminution of dog food

An effective sample preparation is essential for the subsequent analysis of dog food. New technologies and testing methods for example are helping manufacturers and vet supply chains to keep products safe. FRITSCH Mills are perfectly suited for sample preparation prior to further testing of pet food.

-

Using the Impact Rotor and Cutting Rotor for the Variable Speed Rotor Mill PULVERISETTE 14 premium line

By selecting the appropriate accessories, you can also use the Variable Speed Rotor Mill PULVERISETTE 14 premium line as a cutting mill.

-

Grinding of green tea leaves

See how to combine the Variable Speed Rotor Mill PULVERISETTE 14 premium line with the Vibratory Feeder LABORETTE 24 to process green tea leaves.

-

Cryogenic comminution of polymers

In this video we will show you how a cryogenic grinding of polymers with the Variable Speed Rotor Mill PULVERISETTE 14 premium line is conducted.

-

Comminution of animal feed with the Variable Speed Rotor Mill PULVERISETTE 14 premium line

See how quickly a sample of animal feed is milled with the FRITSCH Variable Speed Rotor Mill PULVERISETTE 14 premium line.

-

Recycling of vehicle catalytic converters

In modern three-way catalysts, for example, there are precious metals platinum, rhodium or palladium, or a combination of these. In the laboratory experiment, the ceramic honeycomb body is to be crushed to powder in order to subsequently examine this for the catalytically active precious metals.

-

Processing a catalytic converter in the FRITSCH laboratory

In the laboratory experiment, the ceramic honeycomb body is to be crushed to powder in order to subsequently examine this for the catalytically active precious metals. For this task we used three different FRITSCH laboratory mills.

-

Comminution of latex products

A special property of latex is its extraordinary elasticity, which cannot be matched by any synthetic product. Protective gloves made of latex are used in many industries. However, latex gloves can cause allergies. To prevent allergic reactions, latex products were comminuted for further analysis in the Variable Speed Rotor Mill PULVERISETTE 14 premium line.

-

Comminution of down feathers

Down is a fine thermal insulator and padding used for example in jackets, bedding, pillows and sleeping bags. To prevent the development of allergies, crushed feathers are checked for harmful substances. An effective comminution is the first step for sample preparation.

-

Rock, Paper, Scissors: Ways that Milling and Sample Prep Affect Our Everyday Lives

Find out what the children’s game “Rock, Paper, Scissors” has to do with the science of milling and sample preparation.

-

Premium results with FRITSCH premium line instruments

A never before achieved fineness with a centrifugal mill is attained in a short amount of time with the new FRITSCH PULVERISETTE 14 premium line.

-

The significance of drive power for the efficiency of the Variable Speed Rotor Mill

The aim of all comminution is to achieve a certain fineness. During comminution, particles of a starting material are broken to form many smaller particles.

-

Sample preparation for refuse derived fuels

Plastic, wood and shredded waste, are in times of rising crude oil prices very interesting additions to the classic fuels. Especially in the cement industry, the energy rich fractions from conditioning processes are readily burned along. Important here is the analytical evaluation of the materials.

-

Analysis of lead in toys

Important and always current is the analysis of lead in toys for children. Details about the effective sample comminution.

-

Phytopharmaceuticals, Traditional Chinese Medicine, Natural Cosmetics

Scientists, pharmacists and doctors are increasingly, systematically and more extensively occupied with the components of medical plants. These always have to be analysed.

-