Further Cutting Mills

FURTHER PRODUCT GROUPS

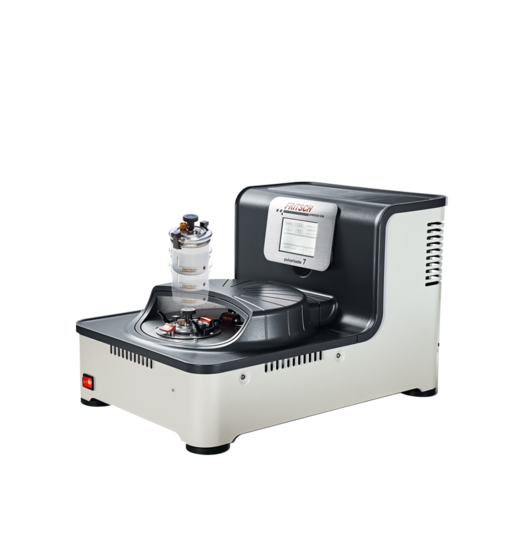

Universal Cutting Mill - variable speed 300-3000 rpm

PULVERISETTE 19 large

-

OVERVIEW

Variable 300 – 3000 rpm for fine comminution of larger amounts

The PULVERISETTE 19 large is our high-speed Universal Cutting Mill with a torque of 30 Nm for the comminution of dry, soft to medium hard samples as well as fibrous materials and plastics with reliable reproducible results with a maximum feed size of 120 x 85 mm and a throughput of 85 l/h.

Due to the variable rotational speed adjustment in increments of hundred between 300 and 3000 rpm you can adjust the comminution for a wide range of applications for each individual sample. The PULVERISETTE 19 large is also ideal for RoHS tests. Due to Clean Design of the PULVERISETTE 19 large, it is easy to clean and offers a safe protection against cross-contamination.

-

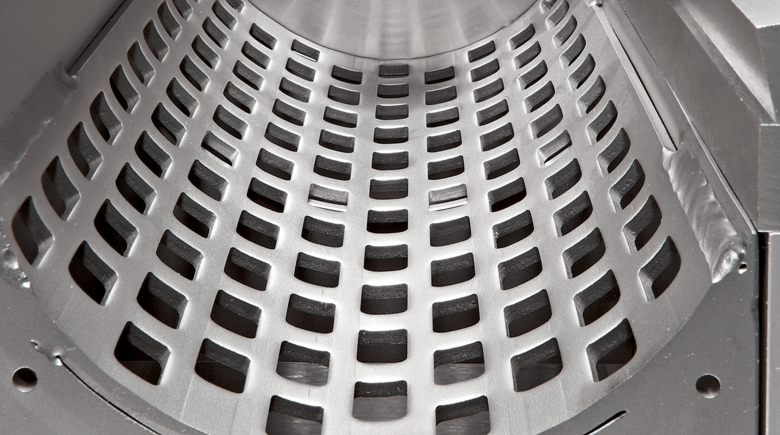

WORKING PRINCIPLE

Unique grinding chamber geometry

The sample material is comminuted according to the cutting principle of scissors between the cutting edges of the rotor and the fixed knives in the grinding chamber until the desired final fineness is achieved. Unique grinding chamber geometry: The grinding chamber is designed with minimal dead space and progressive cutting geometry between rotor and fixed knives. The sample material is continuously moved during comminution and cannot settle anywhere. In conjunctions with the special air flow, this is the basis for swift, blockage-free operation and fast cleaning without residue.

Running stabilisation due to flywheel mass

The Universal Cutting Mill PULVERISETTE 19 large is equipped with a flywheel mass to stabilize the drive torque. This ensures stable operation even for extreme short-term load, as well as an optimal comminution result.

-

FEATURES

- Fast, effective comminution with variable adjustable rotational speed of 300 – 3000 rpm

- Max. feed size 120 x 85 mm

- Throughput of up to 85 l/h

- Defined final fineness due to interchangeable sieve cassettes 0.25 – 20 mm, (further sieve sizes available)

- Collection vessel 3 litres to 10 litres

- Optimised Clean Design for maximum ease of cleaning

- Practical operation directly on the front panel

- Externally adjustable cutting gap

- Maintenance–free 5 kW three-phase motor with frequency converter

- Single-phase versions with maintenance-free three phase frequency converter

- Double cone bearing of the rotor for long service life

- Different rotors for multi-functional use

- Rotor knives and fixed knives are exchangeable for long-lasting quality

- Wear-free labyrinth seals made of stainless steel on both sides of the rotor – on the shaft and in the lid

- Protected funnel with sample pusher

- Optimum airflow for fast comminution and anti-clogging

- Extensive accessories for simplifying your daily work

-

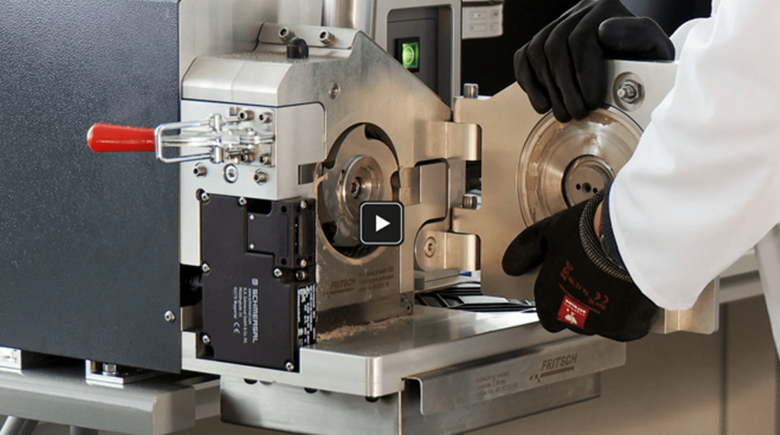

SIMPLE CLEANING

Unmatched easy cleaning!

While you are still tightening the screws on other mills, your FRITSCH Cutting Mill is already clean. Because with just a few simple motions the entire grinding chamber can be opened and rotor and sieve cassette can be removed without tools. The housing and lid can be lifted back completely, and the grinding chamber lid can be completely removed from the hinges.

The result: a completely open empty grinding chamber with minimised dead space for easy quick cleaning and safe protection against cross-contamination.FRITSCH-Plus: The sieve cassettes with square perforation made of stainless steel 316L are laser welded and ensure with less dead space a clearly simpler cleaning.

Removable wear-free labyrinth seals for fast, residue-free cleaning

The labyrinth seals made of stainless steel – on both sides of the rotor as well as on the shaft and in the lid - are wear-free and offer effective contamination protection and no additional heat effect for your samples. -

COLD COMMINUTION - EMBRITTLEMENT

Effective comminution with dry ice and liquid nitrogen

Due to the well-conceived instrument design and the materials used, it is no problem to comminute pre-cooled materials or samples embrittled with liquid nitrogen.

The improved breaking behaviour enables efficient comminution also of sticky, tough-elastic or temperature-sensitive materials with dry ice or after previous embrittlement of the sample with liquid nitrogen. -

COMFORTABLE OPERATION

Complete operation at the front

The well-designed control panel keeps all functions, including the on/off switch, easily accessible on the instrument's front panel. The rotational speed is set in increments of hundred with the plus/minus buttons and shown on the digital display.

-

EQUIPMENT / ACCESSORIES

Configure your Universal Cutting Mill PULVERISETTE 19 large with variable rotational speed of 300 – 3000 rpm exactly to your specific application

The Universal Cutting Mill PULVERISETTE 19 large is delivered without funnel, cutting tool set (consisting of rotors and fixed knives), sieve cassette, collection vessel and stands. Various funnels, collection vessels, rotors and fixed knives, sieve cassettes and stand made of various materials enable you to configure the Universal Cutting Mill exactly for your application.

-

Applications / Solutions

-

In modern three-way catalysts, for example, there are precious metals platinum, rhodium or palladium, or a combination of these. In the laboratory experiment, the ceramic honeycomb body is to be crushed to powder in order to subsequently examine this for the catalytically active precious metals.

-

Processing a catalytic converter in the FRITSCH laboratory

In the laboratory experiment, the ceramic honeycomb body is to be crushed to powder in order to subsequently examine this for the catalytically active precious metals. For this task we used three different FRITSCH laboratory mills.

-

Grinding tarpaper and roofing-bitumen

Tarpaper, Roofing-Bitumen…most people are only familiar with these materials in order to seal roofs, but what happens with this material when a building is torn down?

-

Comminution of punching waste

Non-ferrous metals punching waste respectively recycling materials accrue during the production of electronic components. The production of representative samples can simply be achieved with FRITSCH Cutting Mills.

-