Back to overview

Recycling of vehicle catalytic converters

The vehicle catalytic converter, is used for exhaust gas aftertreatment in vehicles with internal combustion engines. The catalytic converter can drastically reduce pollutant emissions in the exhaust gas. In most cases, the entire exhaust gas aftertreatment system is referred to as a vehicle catalytic converter.

The task of the vehicle catalytic converter is the chemical conversion of the combustion pollutants hydrocarbons (CmHn), carbon monoxide (CO) and nitrogen oxides (NOx) into the non-toxic substances carbon dioxide (CO2), water (H2O) and nitrogen (N2) by oxidation and respectively by reduction. Depending on the operating point of the engine and under optimal operating conditions of the catalytic converter, conversion rates close to 100 % can be achieved.

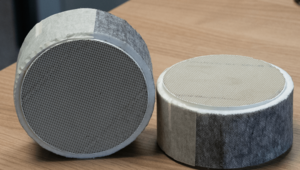

The automotive catalytic converter usually consists of several components. The carrier is a temperature-stable ceramic honeycomb body, usually cordierite, which has a large number of thin-walled channels. The so-called washcoat is located on the carrier. It consists of porous aluminum oxide (Al2O3) and serves to increase the surface area. Due to the high roughness, a large surface area of up to several hundred square meters per gram is realized. The catalytically active substances are embedded in the washcoat. These vary depending on the type of catalyst. In modern three-way catalysts, for example, these are the precious metals platinum, rhodium or palladium, or a combination of these.[1]

In the laboratory experiment, the ceramic honeycomb body is to be crushed to powder in order to subsequently examine this for the catalytically active precious metals.

The first experiment

In the first experiment, the honeycomb body was pre-comminuted in the Universal Cutting Mill PULVERISETTE 19 LARGE. The instrument was equipped with a disk milling cutting rotor with indexable inserts and fixed knives made of hardmetal tungsten carbide, a sieve cassette square perforation 4 mm, as well as a high-performance Cyclone separator made of stainless steel. The grinding time for the sample was about one minute at a speed setting of 1,500 rpm.

Second test

In the second test, a part of the pre-comminuted sample from the PULVERISETTE 19 LARGE, was further processed in the PULVERISETTE 14 premium line. Two hundred milliliters of the sample were comminuted within 38 seconds to a final fineness < 500 µm. The PULVERISETTE 14 premium line was equipped with the cutting rotor, as well as additionally connected to the small volume Cyclone separator, which was operated passively.

Note

In principle, it is possible to achieve a maximum final fineness of the ground sample of < 80 µm when using the Variable Speed Rotor Mill PULVERISETTE 14 premium line.

Third test

In the third test, a part of the pre-comminuted sample from the PULVERISETTE 19 LARGE was further comminuted in the Planetary Mill PULVERISETTE 5 premium line. The grinding time was one minute, the instrument was operated with 125 ml volume zirconium oxide grinding bowls as well as 20 mm zirconium oxide grinding balls. The speed of the sun disk was set to 450 rpm, the final fineness achieved was < 100 µm.

Note

The PULVERISETTE 5 premium line, has the advantage, as it is a closed system, that no harmful substances can be inhaled during the grinding process. Furthermore, the mill offers the possibility to achieve final finenesses of samples down to the nano range

Conclusion

With the conducted tests FRITSCH could show that there are different solutions in the portfolio to comminute catalysts. In a further analysis, the user can determine, for example, how high the precious metal content is in the milled material, in order to decide whether there is potential to recover the precious metals.

-

Download the FRITSCH-report as PDF file

-

Detailed grinding reports

-

Sources and continuative literature

Back to overview