Further Ball Mills

FURTHER PRODUCT GROUPS

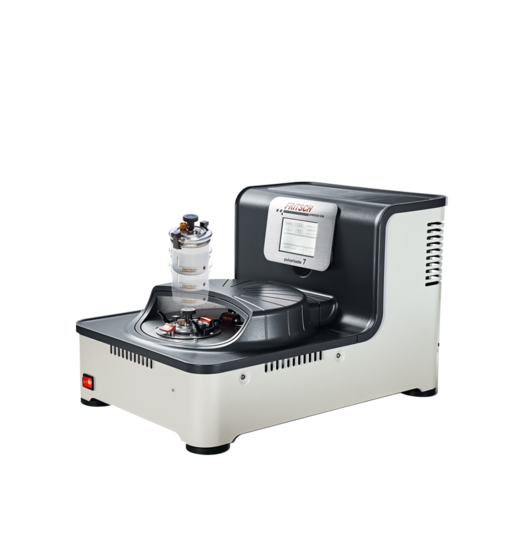

Vibratory Micro Mill

PULVERISETTE 0

-

OVERVIEW

For batchwise fine grinding of small quantities

The Vibratory Micro Mill PULVERISETTE 0 is the ideal laboratory mill for fine comminution of medium-hard, brittle, moist or temperature-sensitive samples – dry or in suspension – as well as for homogenising of emulsions and pastes. The FRITSCH Vibratory Micro Mill PULVERISETTE 0 is recommended for sample preparation of RoHS tests (Restriction of Hazardous Substances).

-

WORKING PRINCIPLE

Impact and Friction

The FRITSCH Vibratory Micro Mill PULVERISETTE 0 grinds your sample through impact and friction by which the mortar vibrates electromagnetically and the grinding material transfers the vibrations to the grinding ball. At the beginning of the grinding, the comminution of the coarse particles is achieved by the impact effect of the grinding ball. Next, the fine particles are comminuted through friction by the tumbling motion of the grinding ball as the vibrations subside. The impact energy of the grinding ball is freely adjustable thus, allowing it to be precisely adapted to the sample being ground.

-

FEATURES

- Adjustable oscillation amplitude for easy adaption of the vibration energy to the grinding sample

- Grinding bowl oscillations 3,000 – 3,600 oscillations/min at 1 – 3 mm amplitude

- Agglomeration phenomena avoided

- Ergonomically positioned membrane keyboard IP65, splash-proofed

- Window for observing the grinding progress

- Digital Timer

- Extensive accessories for simplifying your daily work

-

CRYOGENIC GRINDING

FRITSCH cryo-box

For fast embrittlement of soft, slightly oily, fatty or moist materials, for cryogenic grinding, we offer the FRITSCH cryo-box: Simply insert the filled grinding set into the cryo-box and fill it with liquid nitrogen, with this method even extremely difficult-to-grind samples can be ground down to analysis fineness. And the thick insulation ensures a particularly efficient use of coolant.

-

FINE COMMINUTION AND SIEVING

Comminution and sieving in one unit

For dry and wet sieving, the FRITSCH PULVERISETTE 0 can be converted into to a Vibratory Sieve Shaker for quantitative particle size analysis of solids (measuring range 32 μm – 63 μm) and suspensions (measuring range 20 μm – 10 mm) by simply inserting corresponding sieves.

-

EQUIPMENT / ACCESSORIES

Mortar and grinding balls

The Vibratory Micro Mill PULVERISETTE 0 operates with a mortar, which is equipped with a grinding ball. All FRITSCH mortars are rimmed, regardless of the material, in a robust shell of shock-resistant aluminium, which protects the actual mortar. To optimally adapt the grinding to any sample type, you can choose between 6 different materials, whereby mortars and grinding balls of the same material are generally used. For cryogenic grinding, use mortars and grinding balls made of steel or tungsten carbide.

-

Applications / Solutions

-

Pumpkin plants absorb organochlorine pesticides (OCP), among other things, particularly easily from the soil due to the former conventional cultivation. To ensure a safe product, analyses are a must. Perfectly suited for the correct sample preparation is the Vibratory Micro Mill PULVERISETTE 0.

-

Grindig pumpkin with liquid nitrogen

Pumpkins produce tremendous amounts of foliage, which favour insects and disease. Chemical control is essential, along with cultural control methods. Therefore, rigorous product testing is essential.

-

100 years of experience in comminution now also for the Cannabis industry

What happens when you combine a fourth-generation family business, a century of engineering excellence, a 10,000-year-old medical plant, and an industry worth billions?

-

New Applications for FRITSCH Laboratory Instruments

The directives 2003/108/EC (WEEE) and 2002/95/EC (RoHS) of the European Union have opened up new applications for FRITSCH Laboratory Equipment.

-

Using the FRITSCH PULVERISETTE 0 for RoHS tests

RoHS stands for "Restriction of Hazardous Substances". It's the directive of the European Union (EU) that restricts the use of six hazardous substances in electronic components shipped into Europe. The Vibratory Micro Mill PULVERISETTE 0 was utilized for RoHS tests.

-

From “Boulder” to Nano-Particles

Medium-hard to hard materials with edge lengths up to 95 mm can be pre-crushed with the FRITSCH Jaw Crusher PULVERISETTE 1 so an additional fine comminution with many FRITSCH mills is possible.

-

Restoration success and the preservation of monuments

Natural stones are considered the oldest building materials. Due to the diversity of the basic building blocks and minerals, they are a durable building material with superior aesthetic and robust structural-physical characteristics.With risen environmental pollution worldwide, the damage to the natural stones and to historic basic structures of buildings also increased.

-

Scented toys – analysing allergenic substances

Relatively new on the market are scented toys. Not only do these substances smell good, but they also possess a more or less allergenic potential. Solved was this difficult task of the sample preparation without fragrance being lost.

-

Your cell phone turns into dust

For the sample preparation for the RoHS analysis, several steps are necessary in order to achieve the desired degree of fineness. Optimal here are FRITSCH Mills.

-