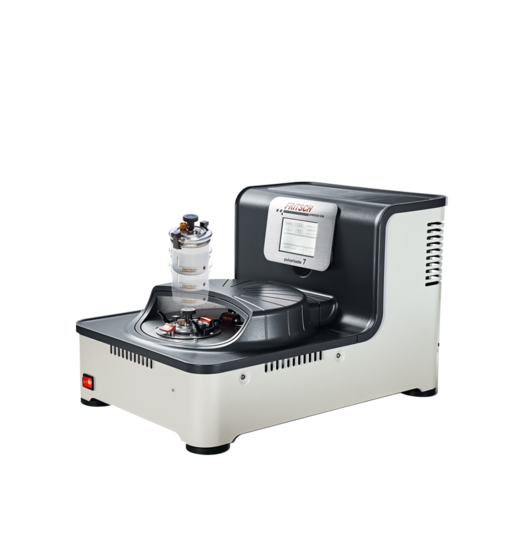

Further Disk Mills

FURTHER PRODUCT GROUPS

Disk Mill

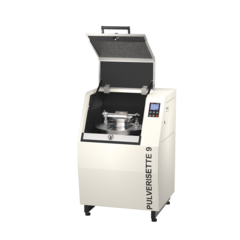

PULVERISETTE 13

classic line-

OVERVIEW

High final fineness for large quantities

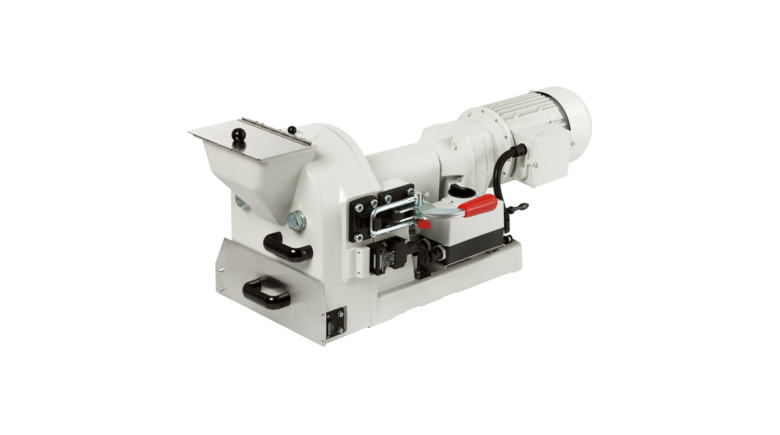

The especially heavy and solid FRITSCH Disk Mill PULVERISETTE 13 classic line is the ideal instrument for fine grinding of up to 150 kg per hour of hard-brittle and medium-hard solids – even in continuous operation. The maximum feed size per piece is approximately 20 mm edge length, the final fineness is freely adjustable between 12 mm and 0.1 mm.

-

WORKING PRINCIPLE

Pressure and shearing action

The material to be ground is comminuted by pressure and shearing action between two counteracting grinding disks with coarse interlocking teeth. The ground material automatically falls down through a pre-set grinding gap into the collection drawer. The desired final fineness can be defined from the outside by changing the gap width.

-

FEATURES

- Feed size up to 20 mm

- max. throughput150 kg/h

- Final fineness 0.1 -12 mm

- Rotational speed grinding disk 440 rpm

- Precise gap adjustment with an accuracy of 0.1 mm

- Especially safe due to central tension lock of the grinding chamber

- Fast, easy cleaning

- Simple operation

- Fast grinding disk change

- Precision setting of the final fineness even during grinding

- High service life due to generously dimensioned bearings

- Easy gap width check from the outside

- Combinable with the Jaw Crusher PULVERISETTE 1 classic line

-

High final fineness in the shortest time

Especially time saving:

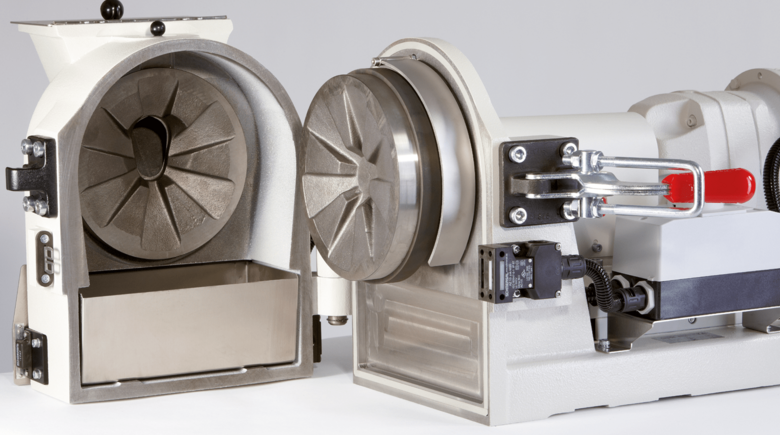

The grinding chamber can be completely opened which makes cleaning especially simple and the grinding disks are very easily accessible for changing.Especially accurate

The precision sliding table of the FRITSCH Disk Mill PULVERISETTE 13 classic line for precise gap adjustment with an accuracy of 0.1 mm – for rapid, precise operation and exactly reproducible grinding results.Safe and easy to clean

The completely accessible grinding chamber makes cleaning particularly easy and the grinding disks particularly accessible for changing. The grinding chamber is locked by a central tension lock with a single motion. The optional dust exhaust system for connecting an extraction device makes it particularly easy to automatically remove the fine dust produced during grinding and is also ideal for cleaning the grinding parts.Practical grinding gap adjustment via precision sliding table

The grinding gap is set via the precision sliding table with 0.1 mm accuracy using a crank - for fast, accurate work and precisely reproducible grinding results. The gap width check can be conducted from the outside (e.g. with thickness gauge).Longer service life of the grinding discs by reversing the direction of rotation

The service life of the grinding discs can be extended simply by reversing the direction of rotation of the maintenance-free three-phase geared motor.Especially solid

The thick-walled housing of the FRITSCH PULVERISETTE 13 classic line consists of recyclable grey cast iron. -

EQUIPMENT / ACCESSORIES

Configure your Disk Mill PULVERISETTE 13 classic line exactly to your specific application

For every FRITSCH Disk Mill PULVERISETTE 13 classic line, you need at least one fixed and one movable grinding disk, which are available in various materials. Normally, two grinding disks of the same material are selected, which must always be harder than the sample to be ground. Grinding disks of zirconium oxide are only suitable for grinding ceramic materials, minerals, etc. and never for hard-tough samples, such as metals.

Metal-free grinding

For completely metal-free grinding of hard-brittle and medium-hard solid samples, for example for dental ceramics, we can equip your FRITSCH Disk Mill PULVERISETTE 13 classic line with a thorough polymer interior coating – together with grinding disks made of zirconium oxide – an absolutely reliable protection against iron contamination.

View extensive accessoriesThe powerful combination for pre- and fine-crushing in a single step

For fast, continuous pre- and fine-grinding particularly of large quantities of coarse material, the combination of the FRITSCH Disk Mill PULVERISETTE 13 classic line and the FRITSCH Jaw crusher PULVERISETTE 1 classic line is the ideal solution. Mounted together onto a rack and connected to each other by a chute, they automatically grind the material from a particle size of up to 95 mm to a final fineness of down to 100 μm – fast, easy and effective in a single step!

Read details about the combination of the Disk Mill PULVERISETTE 13 classic line and Jaw Crusher PULVERISETTE 1 classic line

-

Applications / Solutions

-

Medium-hard to hard materials with edge lengths up to 95 mm can be pre-crushed with the FRITSCH Jaw Crusher PULVERISETTE 1 so an additional fine comminution with many FRITSCH mills is possible.

-

Pigment processing: The isolation of the naturally beautiful

Mankind has always enjoyed enduring works of art. The particles of the pigments have always been playing a major role. For example, the oldest cave paintings still impress us today. One of the most renowned experts for the production of historical pigments is Dr. Kremer from Aichstetten (Bavaria, Germany). FRITSCH laboratory mills are of great importance in Dr. Kremer's pigment processing.

-