Further Cutting Mills

FURTHER PRODUCT GROUPS

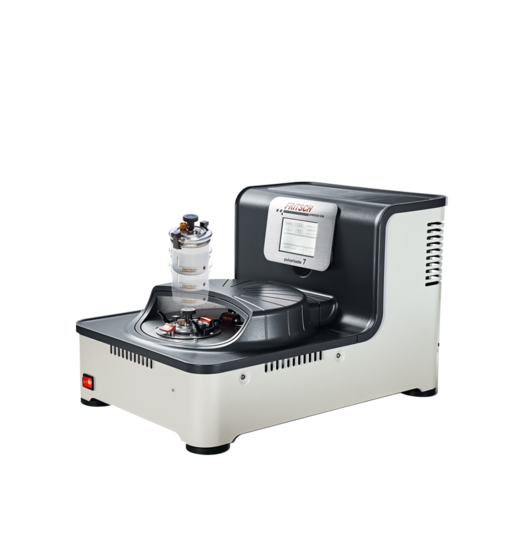

Universal Cutting Mill - variable speed 300-3000 rpm

PULVERISETTE 19

Configure your Universal Cutting Mill PULVERISETTE 19 with variable rotational speed of 300 – 3000 rpm exactly to your specific application.

Please choose from our extensive accessories at least a funnel, cutting tool set, sieve cassette and collecting vessel.

Funnel

Funnel for long and bulk solids made of plastic or stainless steel 316L or protected funnel made of stainless steel or stainless steel 316L with plastic sample pusher

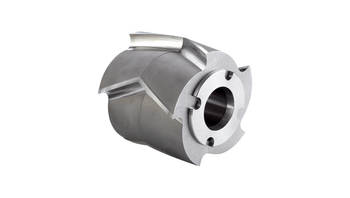

Cutting tool sets

Rotor with V-cutting edges and fixed knives made of hardened stainless steel, hardmetal tungsten carbide or chromium-free tool steel or

rotor with notched edges and fixed knives made of hardened stainless steel and stainless steel 316L or

rotor with straight cutting edges and fixed knives made of stainless steel, stainless steel 316L or chromium-free tool steel or disk milling cutter rotors with indexable inserts and fixed knives made of hardmetal tungsten carbide

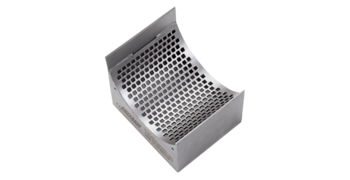

Sieve cassettes

Sieve cassettes with trapezoidal or square perforation made stainless steel 316L or chromium-free steel DC01

Collecting vessels

Collecting vessel 3 litres or collecting vessel for large quantities 10 litres

Optional Accessories

Stand: Universal support stand, stand made of stainless steel 316L, stand with wheels or table-top stand

Sample exhaustion with Cyclone separators: High-performance Cyclone separator or small volume Cyclone separator

Certification: IQ/OQ-Documentation to support instrument qualification

PLC module: A PLC module for controlling the Cutting Mill via a PLC control system and the physical connection based on a RS485 bus are available on request.

FUNNELS

The PULVERISETTE 19 can either be used with a funnel for long and bulk solids made of plastic or stainless steel 316L for feeding materials at their full length or a protected funnel made of stainless steel or stainless steel 316L with a plastic sample pusher for all other materials.

FUNNELS

With the FRITSCH standard funnel free-flowing bulk solids as well as straw, films or similar materials can be inserted at full length. Both ends of the plunger of the funnel for long and bulk solids can be utilised: the small end for adding of long goods and the wide end for bulk solids.

| 1. Stopper-Body | |

| General specifications | |

| Material | Aluminium AlZnMgCu1,5 |

| ISO/EN/DIN Code | 3.4365 |

| Chemical composition | |

| Element | Share % | Iron – Fe | 0.50 |

| Silicon – Si | 0.40 |

| Copper – Cu | 1.2 - 2.0 |

| Manganese – Mn | 0.30 |

| Magnesium – Mg | 2.1 - 2.9 |

| Chromium– Cr | 0.18 - 0.28 |

| Zinc - Zn | 5.1 - 6.1 |

| Titan – Ti | 0.20 |

| Physical and mechanical properties | |

| Density | 2.7 g/cm³ |

| Hardness | 2.75 Mohs |

| 2. Fillingtube | |

| General specifications | |

| Material | Stainless steel – 1.4301 |

| ISO/EN/DIN code | X5CrNi1810 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 66.805 |

| Carbon – C | 0.070 |

| Silicon – Si | 1.000 |

| Manganese – Mn | 2.000 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.030 |

| Chromium – Cr | 19.5 |

| Nickel – Ni | 10.5 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 7.8 g/cm³ |

| Hardness | HRB 96 |

Explanations on hardness data

The protected funnel with sample pusher enables due to the sample pusher a good handling and an outstanding material feeding.

| General specifications | |

| Material | Stainless steel – 1.4301 |

| ISO/EN/DIN code | X5CrNi1810 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 66.805 |

| Carbon – C | 0.070 |

| Silicon – Si | 1.000 |

| Manganese – Mn | 2.000 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.030 |

| Chromium – Cr | 19.5 |

| Nickel – Ni | 10.5 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 7.8 g/cm³ |

| Hardness | HRB 96 |

Explanations on hardness data

The protected funnel made in a corrosion-resistant stainless steel version 316L with sample pusher is ideal for applications in the food and pharmaceutical industry. This funnel enables due to the sample pusher a good handling and an outstanding material feeding.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Funnel for long- and bulk solids made in a corrosion-resistant stainless steel version 316L for applications in the food and pharmaceutical industry.

With this FRITSCH funnel free-flowing bulk solids as well as straw, films or similar materials can be inserted at full length. Both ends of the plunger of the funnel for long and bulk solids can be utilised: the small end for adding of long goods and the wide end for bulk solids.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

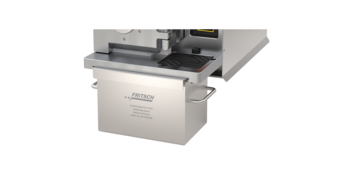

COLLECTING VESSELS made of stainless steel 316L

A collection vessel with 3 litres volume is available. For the comminution of larger amounts the collection vessel 10 litre volume is recommended.

Collection vessels are also available in further sizes.

COLLECTING VESSELS

This collecting vessel has a volume of 3 litres. Collecting vessels (stainless steel are available in various sizes).

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

This collecting vessel is recommended for the comminution of larger sample amounts and has a volume of 10 litres.

Collecting vessels (stainless steel are available in various sizes).

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

CUTTING TOOL SETS

-

Material data for cutting tool sets and application recommendation

Material and rotor type Main component of material Abrasion resistance Density g/cm³ Suitable for comminution of Hardened, stainless steel Fe - Cr fairly good 7.7 Standard rotor with V-cutting edges and fixed knives

order no. 45.5100.00

Rotor with notched edges and fixed knives

order no. 45.5192.00

Rotor with straight cutting edges and fixed knives

order no. 45.5185.00medium-hard, brittle samples and for tough-elastic materials and films

medium-hard, brittle, fibrous and elastic samples and for samples with residual moisture, such as food, feed or plants, and temperature-sensitive samples, such as plastics

medium-hard, brittle samples and for easily cut material, such as hay, straw, fibrous or biological materialsStainless steel 316L Fe - Cr fairly good 8.0 Rotor with notched edges and fixed knives

order no. 45.5198.00medium-hard, brittle, fibrous and elastic samples, ideal for comminution of samples with residual moisture, such as food, feed or plants and for temperature-sensitive samples like for example plastics, resistant to alkalis and acids, complies with the guidelines of the food and pharmaceutical industry perfect for the analytical sector, increased resistance to corrosion Hardmetal tungsten carbide WC very good 12.4 Rotor with V-cutting edges and fixed knives order no 45.5370.00

Disk milling cutter rotor with indexable inserts and fixed knives

order no. 45.5200.00hard, abrasive samples and hard-tough materials

hard, abrasive samples and scrap circuit board with glass fibre residue and copper cable

The PULVERISETTE 19 can either be equipped with a Rotor with V-cutting edges and fixed knives or rotor with straight cutting edges and fixed knives, or rotor with notched edges and fixed knives or disk milling cutter rotor with indexable inserts and fixed knives.

By selecting the material of the cutting tool sets and sieve cassettes, the abrasion properties can also be individually accommodated. Details about cutting rotors and materials are found in the element analysis.

Cutting tool sets are also available in further materials.

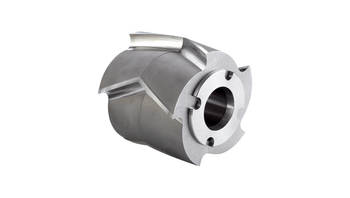

CUTTING TOOL SET MADE OF HARDENED STAINLESS STEEL AND HARDMETAL TUNGSTEN CARBIDE

The standard rotor made of hardened, stainless steel with V-cutting edges and fixed knives is suited primarily for comminution of tough-elastic materials and films due to its especially acute cutting angle and the high cutting action that results.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our cutting tool sets of chromium-free tool steel.

| Standard rotor with V-cutting edges and fixed knives | |

| General specifications | |

| Material | Stainless steel – 1.4112 |

| ISO/EN/DIN code | X90CrMoV18 / EN 10088 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 79 - 77 |

| Chromium – Cr | 17 - 19 |

| Silicon – Si | 1.0 |

| Manganese – Mn | 1.0 |

| Molybdenum – Mo | 0.9 - 1.3 |

| Carbon – C | 0.85 - 0.95 |

| Vanadium – V | 0.07 - 0.012 |

| Phosphorus – P | 0.04 |

| Sulphur – S | 0.015 |

| Physical and mechanical properties | |

| Density | 7.7 g/cm³ ; |

| Hardness | 56 - 58 HRC |

Explanations on hardness data

This rotor with V-cutting edges and fixed knives made of hardmetal tungsten carbide comminutes the grinding material through impact and cutting forces and is suitable for hard-tough materials.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our cutting tool sets of chromium-free tool steel.

| 1. Rotorknives | |

| General Specification | |

| Material | Hardmetal tungsten carbide – WC |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – WC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 12.4 g/cm³ |

| Hardness | 89.5 HRA |

| 2. Rotorbody | |

| General specifications | |

| Material | Stainless steel– 1.4404 |

| ISO/EN/DIN Code | X2CRNiMO17-12-2 /DIN SEW410 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 68.3 - 62.8 |

| Chromium – Cr | 16.5. - 18.5 |

| Nickel – Ni | 10.0 - 13.0 |

| Molybdenum – Mo | 2.0 - 2.5 |

| Manganese – Mn | 2.0 |

| Silicon – Si | 1.0 |

| Phosphorus – P | 0.045 |

| Carbon – C | 0.03 |

| Sulphur – S | 0.015 |

| Other – | 0.11 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 45 HB |

Explanations on hardness data

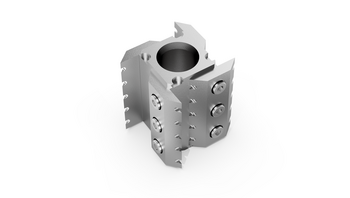

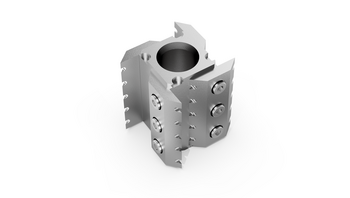

The rotor with notched edges and fixed knives made of hardened stainless steel is ideal for comminuting samples with residual moisture, such as food, feed or plants, and temperature-sensitive samples, such as plastics.

Due to its notched edges, the grinding chamber never closes completely, thus allowing optimum air flow. This significantly increases the throughput and makes the use of very fine sieves for larger quantities possible in the first place. The rotor knives have two notched cutting edges and can be easily turned after one side is used up.

Your advantage: twice the service life.

| Standard rotor with V-cutting edges and fixed knives | |

| General specifications | |

| Material | Stainless steel – 1.4112 |

| ISO/EN/DIN code | X90CrMoV18 / EN 10088 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 79 - 77 |

| Chromium – Cr | 17 - 19 |

| Silicon – Si | 1.0 |

| Manganese – Mn | 1.0 |

| Molybdenum – Mo | 0.9 - 1.3 |

| Carbon – C | 0.85 - 0.95 |

| Vanadium – V | 0.07 - 0.012 |

| Phosphorus – P | 0.04 |

| Sulphur – S | 0.015 |

| Physical and mechanical properties | |

| Density | 7.7 g/cm³ ; |

| Hardness | 56 - 58 HRC |

Explanations on hardness data

The rotor with notched edges and fixed knives made of stainless steel 316L is ideal for comminuting samples with residual moisture, such as food, feed or plants, and temperature-sensitive samples, such as plastics.

Due to the material used, the rotor is resistant to alkalis and acids and complies with the guidelines of the food and pharmaceutical industry – thus it’s perfect for the analytical sector and for sample preparation with special focus on increased resistance to corrosion.

Due to its notched edges, the grinding chamber never closes completely, thus allowing optimum air flow. This significantly increases the throughput and makes the use of very fine sieves for larger quantities possible in the first place. The rotor knives have two notched cutting edges and can be easily turned after one side is used up.

Your advantage: twice the service life.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The rotor made of tool steel with straight cutting edges which run parallel to the fixed knives is suitable for easily cut material, such as hay, straw, fibrous or biological materials. The rotor knives may be turned, since they have 2 cutting edges. Your advantage: doubling the life span of your rotor knives.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our cutting tool sets of chromium-free tool steel.

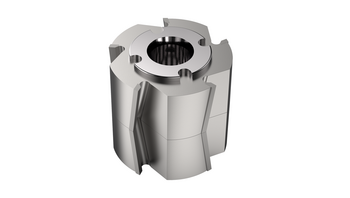

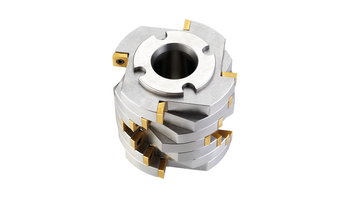

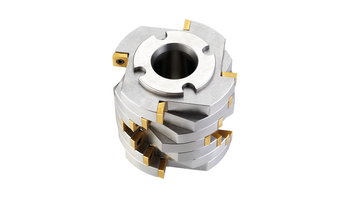

Disk milling cutter rotor: The especially robust disk milling cutter rotor with indexable inserts and fixed knives made of hardmetal tungsten carbide can even comminute circuit board scrap with glass fibre residue and copper cable.

Quadruple service life: With the disk milling cutter rotor, the cutting plates can be turned four times and replaced individually. Damage or wear are no longer a reason to buy a completely new rotor.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our cutting tool sets of chromium-free tool steel.

| 1. Rotorknives | |

| General Specification | |

| Material | Hardmetal tungsten carbide – WC |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – WC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 12.4 g/cm³ |

| Hardness | 89.5 HRA |

| 2. Rotorbody | |

| General specifications | |

| Material | Stainless steel– 1.4404 |

| ISO/EN/DIN Code | X2CRNiMO17-12-2 /DIN SEW410 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 68.3 - 62.8 |

| Chromium – Cr | 16.5. - 18.5 |

| Nickel – Ni | 10.0 - 13.0 |

| Molybdenum – Mo | 2.0 - 2.5 |

| Manganese – Mn | 2.0 |

| Silicon – Si | 1.0 |

| Phosphorus – P | 0.045 |

| Carbon – C | 0.03 |

| Sulphur – S | 0.015 |

| Other – | 0.11 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 45 HB |

Explanations on hardness data

The disk milling cutter rotor with large chip chambers, indexable inserts and fixed knives made

of hardmetal tungsten carbide is suited for grinding large sample amounts.

The especially robust disk milling cutter rotor with large chip chambers, indexable inserts and fixed knives can even comminute circuit board scrap with glass fibre residue and copper cable.

Quadruple service life: With the disk milling cutter rotor, the cutting plates can be turned four times and replaced individually. Damage or wear are no longer a reason to buy a completely new rotor.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our cutting tool sets of chromium-free tool steel.

| 1. Rotorknives | |

| General Specification | |

| Material | Hardmetal tungsten carbide – WC |

| Chemical composition | |

| Element | Share % |

| Tungsten carbide – WC | 88 |

| Cobalt – Co | 12 |

| Physical and mechanical properties | |

| Density | 12.4 g/cm³ |

| Hardness | 89.5 HRA |

| 2. Rotorbody | |

| General specifications | |

| Material | Stainless steel– 1.4404 |

| ISO/EN/DIN Code | X2CRNiMO17-12-2 /DIN SEW410 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 68.3 - 62.8 |

| Chromium – Cr | 16.5. - 18.5 |

| Nickel – Ni | 10.0 - 13.0 |

| Molybdenum – Mo | 2.0 - 2.5 |

| Manganese – Mn | 2.0 |

| Silicon – Si | 1.0 |

| Phosphorus – P | 0.045 |

| Carbon – C | 0.03 |

| Sulphur – S | 0.015 |

| Other – | 0.11 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 45 HB |

Explanations on hardness data

Sieve cassettes made of stainless steel 316L

Sieve cassettes determine the fineness of a sample. Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

Sieve cassettes are also available in further perforations.

SIEVE CASSETTE MADE OF STAINLESS STEEL 316L

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band. They are laser-welded and offer significantly easier cleaning due to less dead spaces. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achiving medium fineness with a narrow grain band. They are laser-welded and offer significantly easier cleaning due to less dead spaces. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band. They are laser-welded and offer significantly easier cleaning due to less dead spaces. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band. They are laser-welded and offer significantly easier cleaning due to less dead spaces. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Sieve cassettes determine the fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with square perforations are used for the grinding of brittle materials and for achieving medium fineness with a narrow grain band. They are laser-welded and offer significantly easier cleaning due to less dead spaces. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action.

For sample preparation according to RoHS (for the evidence of hexavalent chromium) and for the XRF-analysis we recommend our sieve cassettes made of chromium-free tool steel.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

ACCESSORIES FOR CHROMIUM-FREE COMMINUTION

-

Material data for chromium-free cutting tool sets and application recommendation

Material and rotor type Main component of material Abrasion resistance Density g/cm³ Suitable for comminution of Chromium-free tool steel Fe fairly good 7.8 Rotor with V-cutting edges and fixed knives

order no. 45.5112.00

Rotor with straight cutting edges and fixed knives

order no. 45.5012.00

Both rotors are recommended for sample preparation according to RoHS for example for verification of hexavalent chromium or XRF analysis.brittle, hard samples, tough-elastic materials and films

brittle, hard samples, easily cut material, such as hay, straw, fibrous or biological materials

When chromium-free size reduction is required for sample preparation according to RoHS – for example for verification of hexavalent chromium – or for XRF analysis, FRITSCH cutting tool sets of chromium-free tool steel and sieve cassettes made of chromium-free steel DC01 offer absolute assurance.

CUTTING TOOL SET MADE OF CHROMIUM-FREE TOOL STEEL

The rotors made of chromium-free tool steel are especially recommended for the sample preparation according to RoHS and for the XRF-analysis. If a chromium-free size reduction is required for sample preparation according to RoHS – for example for verification of hexavalent chromium – or for XRF analysis, FRITSCH cutting tool sets of chromium-free tool steel offer this absolute assurance. Because for FRITSCH Cutting Mills, the fixed knives are always of the same material as the cutting edges of the rotor.

This rotor with V-cutting edges and fixed knives made of chromium-free tool steel is suited primarily for comminution of tough-elastic materials and films due to its especially acute cutting angle and the high cutting action that results.

For all other applications we recommend our cutting tool set made of tool steel and hardmetal tungsten carbide, since these are harder and therefore more resilient against abrasion.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

The rotors made of chromium-free tool steel are especially recommended for the sample preparation according to RoHS and for the XRF-analysis. If a chromium-free size reduction is required for sample preparation according to RoHS – for example for verification of hexavalent chromium – or for XRF analysis, FRITSCH cutting tool sets of chromium-free tool steel offer this absolute assurance. Because for FRITSCH Cutting Mills, the fixed knives are always of the same material as the cutting edges of the rotor.

The rotor made of chromium-free tool steel with straight cutting edges which run parallel to the fixed knives is suitable for easily cut material, such as hay, straw, fibrous or biological materials. The rotor knives may be turned, since they have 2 cutting edges. Your advantage: doubling the life span of your rotor knives.

For all other applications, we recommend our cutting tool set made of tool steel and hardmetal tungsten carbide, since these are harder and therefore more resilient against abrasion.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

SIEVE CASSETTES MADE OF CHROMIUM-FREE STEEL DC 01

Sieve cassettes determine the final fineness of a sample. Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

Sieve cassettes made of chromium-free steel DC01 are especially recommended for the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF analysis. For all other applications sieve cassettes made stainless steel can be used since these are harder and therefore more resilient against abrasion.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

Sieve cassettes made of chromium-free steel DC01 are especially recommended for the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF analysis. For all other applications sieve cassettes made stainless steel can be used since these are harder and therefore more resilient against abrasion.

Sieve cassettes determine the final fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

Sieve cassettes made of chromium-free steel DC01 are especially recommended for the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF analysis. For all other applications sieve cassettes made stainless steel can be used since these are harder and therefore more resilient against abrasion.

Sieve cassettes determine the final fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

Sieve cassettes made of chromium-free steel DC01 are especially recommended for the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF analysis. For all other applications sieve cassettes made stainless steel can be used since these are harder and therefore more resilient against abrasion.

Sieve cassettes determine the final fineness of a sample.

Sieve inserts with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

Sieve cassettes made of chromium-free steel DC01 are especially recommended for the sample preparation according to RoHS or for verification of hexavalent chromium and for the XRF analysis. For all other applications sieve cassettes made stainless steel can be used since these are harder and therefore more resilient against abrasion.

Sieve cassettes determine the final fineness of a sample.

Sieve cassettes with trapezoidal and square perforations are offered. Sieve cassettes with trapezoidal perforations improve size reduction through extra shearing action. Sieve cassettes with square perforations are used for the grinding of brittle materials and materials of medium fineness with a narrow grain band.

| General specifications | |

| Material | Construction steel - 1.0330 - not rust-proof |

| ISO/EN/DIN code | DC01, EN 1013 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 99.19 |

| Carbon – C | 0.12 |

| Manganese – Mn | 0.6 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.045 |

| Physical and mechanical properties | |

| Density | 7.85 g/cm³ |

| Hardness | 86 HRA |

Explanations on hardness data

Sample exhaustion with Cyclone separators

The patented combination of the Universal-Cutting Mill with the high-performance Cyclone separator and the small volume Cyclone separator enables a simple cleaning and feeding, the use of finer sieve cassettes for achieving a higher final fineness, increases the throughput and reduces the thermal load of the samples – even for materials, which are otherwise difficult to grind.

Select Cyclone separator, exhaust system and accessories.

High-Performance Cyclone separator

The FRITSCH high-performance Cyclone separator completely made of stainless steel 316L is particularly indispensable in the analytical sector and in the food and pharmaceutical industries, and for the processing of heterogeneous mixtures of material, e.g. in the cement industry.

Due to its high surface quality, it offers enhanced resistance to corrosive media such as alkalis and acids and is especially easy to clean with a wide range of possible cleaning agents, without leaving any residues. The comminuted sample is drawn into a screwed-on collecting vessel or in a smaller sample glass, in which it can also be transported and stored. In addition, it can be completely dismantled, fully emptied, flooded and sterilised, and thus offers reliable protection against cross-contamination.

The advantages of the high-performance Cyclone separator at a glance

- Faster throughput

- Improved discharge of material from the grinding chamber

- Additional strong cooling of the grinding material and grinding parts

- Efficient size reduction of temperature-sensitive samples, electrostatically-charged plastics or powder coatings

- Ideal for light materials, small sample quantities and finer sieve sizes

- Highly efficient continuous comminution of large quantities

The FRITSCH high-performance Cyclone separator completely made of stainless steel 316L is particularly indispensable in the analytical sector and in the food and pharmaceutical industries, and for the processing of hetero geneous mixtures of material, e.g. in the cement industry. Due to its high surface quality, it offers enhanced resistance to corrosive media such as alkalis and acids and is especially easy to clean with a wide range of possible cleaning agents, without leaving any residues. In addition, it can be completely dismantled, fully emptied, flooded and sterilised, and thus offers reliable protection against cross-contamination. The comminuted sample is drawn into a screwed-on collecting vessel or in a smaller sample glass, in which it can also be transported and stored.

The high-performance Cyclone separator with solid piping should be used in combination with the stand with wheels (order no. 45.5800.00).

The advantages of the high-performance Cyclone separator at a glance

- Faster throughput

- Improved discharge of material from the grinding chamber

- Additional strong cooling of the grinding material and grinding parts

- Efficient size reduction of temperature-sensitive samples, electrostatically-charged plastics or powder coatings

- Ideal for light materials, small sample quantities and finer sieve sizes

- Highly efficient continuous comminution of large quantities

| General specifications | |

| Material | Stainless steel – 1.4301 |

| ISO/EN/DIN code | X5CrNi1810 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | 66.805 |

| Carbon – C | 0.070 |

| Silicon – Si | 1.000 |

| Manganese – Mn | 2.000 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.030 |

| Chromium – Cr | 19.5 |

| Nickel – Ni | 10.5 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 7.8 g/cm³ |

| Hardness | HRB 96 |

Explanations on hardness data

Collecting Vessel for High-performance Cyclone separator

Sample glass 1 litre for sample exhaustion with the high-performance Cyclone separator.

The sample glass with 2 litres volume is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

The sample glass with 5 litres volume is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

The collecting vessel 20 litres is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

The collecting vessel 60 litres is recommended for sample exhaustion with the high-performance Cyclone separator for sample discharges larger than 1000 ml, since only a 1 litre sample glass is included in the delivery of the high-performance Cyclone separator.

| General specifications | |

| Material | Stainless steel – 1.4404/316L |

| ISO/EN/DIN code | X2CrNiMo17-12-2 |

| Chemical composition | |

| Element | Share % |

| Iron – Fe | approx. 62.8 |

| Carbon – C | 0.03 |

| Silicon – Si | 1 |

| Manganese – Mn | 2 |

| Phosphorus – P | 0.045 |

| Sulphur – S | 0.015 |

| Chromium – Cr | 18.5 |

| Molybdenum – Mo | 2.50 |

| Nickel – Ni | 13.00 |

| Nitrogen – N | 0.110 |

| Physical and mechanical properties | |

| Density | 8.0 g/cm³ |

| Hardness | 215 HB |

Explanations on hardness data

Small Volume Cyclone Separator

Small volume Cyclone separator made of plastic for sample exhaustion of small sample quantities, incl. 500 ml sample glass.

Especially for exhaustion of small sample quantities, we designed the compact FRITSCH small volume Cyclone separator. It is made of plastic, can be dismantled completely and cleaned in a dishwasher for reliably preventing contaminations. The FRITSCH small volume Cyclone separator must be connected to an exhaust system: order no. 43.9070.00.

Especially convenient: The comminuted sample is drawn directly into the screwed-on 500 ml sample glass, in which it can also be transported and stored. Alternatively a sample glass 250 ml can also be screwed-on and ordered: order no. 27.1450.00.

Collecting vessels for small volume Cyclone separator

Sample bottle with screw lid, thread of sample bottle GL55, sample bottle can be used with dividing heads, division ratio 1:8 and 1:10.

Furthermore a sample vessel 32 ml with lid, article-number 83.3190.16, is available, which can be inserted in the sample bottles 250 ml and 500 ml for dividing smallest sample quantities.

The sample glass is recommended for sample exhaustion with the small volume Cyclone separator for sample discharges smaller than 500 ml, since only a 500 ml sample glass is included in the delivery of the small volume performance Cyclone separator.

Sample bottle with screw lid, thread of sample bottle GL55.

Sample bottle can be used with dividing heads, division ratio 1:8.

Furthermore a sample vessel 32 ml with lid, article-number 83.3190.16, is available, which can be inserted in the sample bottles 250 ml and 500 ml for dividing smallest sample quantities.

Sample glass can also be used for sample exhaustion with the small volume Cyclone separator.

Exhaust system and accessories for High-performance and Small Volume Cyclone Separator

With the switch box, you control the exhaust system directly via the Universal Cutting Mills PULVERISETTE 19. Due to the switch box, applicable for 100-240 V/1~, 50-60 Hz, up to 3600 Watt, the sample exhaustion with Cyclone separators and exhaust system becomes even easier and more comfortable.

The exhaust system, dust category "M" according to DIN EN 60335-2-69 for 230 V/1~, 50/60 Hz, 1600 Watt is versatile:

For combination with the high performance and small volume cyclones.

To operate the FRITSCH Cyclones you need an exhaust system. The strong airflow ensures simple feeding, increases throughput, and reduces the thermal load of the samples. The high performance and small volume Cyclone separator can be combined with Universal Cutting Mills PULVERISETTE 19, the Variable Speed Rotor Mill PULVERISETTE 14 premium line and classic line. The small volume cyclone can also be combined with the Variable Speed Rotor Mill PULVERISETE 14 premium line and classic line even for passive utilisation – without sample exhaust.

The high-performance cyclone is ideal for combination with the Universal Cutting Mills PULVERISETTE 19 large, the Cross Beater Mill PULVERISETTE 16 and the Disk Mill PULVERISETTE 13 premium line for optimal sample extraction and for comminution of larger quantities.

For cooling of the Variable Speed Rotor Mill PULVERISETTE 14 premium line

By connecting the exhaust system with the connecting piece order no. 14.8128.00, the cooling of the mill can easily be enhanced.

For connecting to Disk Mill PULVERISETTE 13 premium line

The exhaust is simply connected to the PULVERISETTE 13 premium line and operated via a start and stop button on the instrument – for dust free comminution.

For connecting to the Jaw Crusher PULVERISETTE 1, Modell I + II classic line

Simply connect the exhaust system to the integrated connection of the PULVERISETTE 1. Fine dust arising during comminution is automatically removed. The exhaust system is also very useful when cleaning the grinding parts.

For connecting to the Disk Mill PULVERISETTE 13 classic line

The exhaust system can be easily connected to the PULVERISETTE 13 classic line. Fine dust arising during comminution is automatically removed. The exhaust system is also very useful when cleaning the grinding parts.

For exhaustion of the sample during dry measurement with the Laser Particle Sizers ANALYSETTE 22 NeXT

An exhaust system is necessary to ensure automatic sample exhaustion during dry measurement. When the measurement is completed it can also be easily used to manually clean the feeder.

Please note that the exhaust system article no. 43.9070.00, is not equipped with a fine filter and therefore dust may escape. Please consider the valid occupational health and safety regulations. This exhaust system is mostly recommended for dust-free grinding and the vacuuming of during the process developing fine dust in the upper part of the grinding chamber and for the cleaning of the grinding parts.

For vacuuming of the sample during dry measurement with the Laser Particle Sizers ANALYSETTE 22 NeXT, we recommended we recommend the exhaust system article no. 43.9060.00, which is equipped with a hose and an ultra-fine filter of dust class "H" according to DIN EN 60335-2-69, so that the escape of fine dust is reduced.

1 pack = 5 pieces

One pack is included in the scope of delivery of the exhaust system (article No. 43.9070.00).

These fleece filter bags should be used for the vacuuming off of fine, dry materials.

For the vacuuming off of coarse, wet materials are plastic bags available (article no. 43.9052.00).

1 pack = 5 pieces

One pack is included in the order of the exhaust system (article No. 43.9070.00).

These plastic bags should be used for the vacuuming off of coarse, wet materials.

For the vacuuming off of fine, dry materials are paper filter bags available (article no. 43.9055.00).

STANDS

An universal support stand, a support stand made of stainless steel and a support stand with wheels are available. The stands offer a solid, space-saving and spatially variable basis for the mill.

STANDS

Stand for free installation of the following devices:

Universal Cutting Mill PULVERISETTE 19 variable speed 300-3000 rpm

Universal Cutting Mill PULVERISETTE 19 variable speed 50-700 rpm

Universal Cutting Mill PULVERISETTE 19 variable speed 50-700 rpm large

Universal Cutting Mill PULVERISETTE 19 variable speed 300-3000 rpm Large

Cross Beater Mill PULVERISETTE 16 with grinding insert made of cast iron

Cross Beater Mill PULVERISETTE 16 with grinding insert made of stainless steel

The PULVERISETTE 19 is shown as an example in the photo.

Stand cpl. welded, electrochemically polished made of stainless steel 316L.

This stand is also recommended and used for the free installation the following models of the Universal-Cutting Mills PULVERISETTE 19 300-3000 rpm and 50-700 rpm in the corrosion resistant stainless steel version 316 L, as well as for the PULVERISETTE 19 large 300-3000 rpm and PULVERISETTE 19 large 50-700 rpm.

The stand with wheels offers the Universal Cutting Mills PULVERISETTE 19 a space-saving and spatially variable basis.

A table-top stand with a height of approx. 330 mm is offered for the Universal Cutting Mills, Both, the PULVERISETTE 19 and PULVERISETTE 19 large can simply be screwed onto the stand.

CERTIFICATION

IQ/OQ documentation (questionnaire format - implementation not included) for the independent utilization for the support of instrument qualification in the quality management system for the Universal Cutting Mill PULVERISETTE 19.

CERTIFICATION

IQ/OQ documentation (questionnaire format - implementation by customer) for the independent utilization for the support of instrument qualification in the quality management system for the Universal Cutting Mills PULVERISETTE 19.