Further Planetary Mills

FURTHER PRODUCT GROUPS

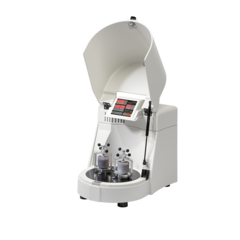

Planetary Micro Mill

PULVERISETTE 7

premium line-

OVERVIEW

FRITSCH Planetary Ball Mills – high-performance all-rounder in routine laboratory work

The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of applications and ideally suited for loss-free grinding down to a final fineness of 100 nm of hard, medium-hard and brittle materials. Depending on the desired final fineness, the grinding can be performed dry, in suspension or in inert gas.

In addition to comminution, you can also use Planetary Mills for mixing and homogenising emulsions and pastes or for mechanical activation and alloying in materials research. -

WORKING PRINCIPLE

Comminution according to the Planetary-Principle

The comminution takes place primarily through the high-energy impact of grinding balls and partially through friction between grinding balls and the grinding bowl wall. To achieve this, the grinding bowl, containing the material to be ground and grinding balls, rotates around its own axis on a main disk rotating in the opposite direction. At a certain speed, the centrifugal force causes the ground sample material and grinding balls to bounce off the inner wall of the grinding bowl, cross the bowl diagonally at an extremely high speed and impact the material to be ground on the opposite wall of the bowl.

Due to sunken grinding bowls, the high-performance Planetary Micro Mill PULVERISETTE 7 premium line reaches unprecedented relative rotational speeds of the grinding of up to 2,200 rpm and centrifugal accelerations of 95 times the force of gravity. Thereby is the application of energy approximately 150 % above that of conventional Planetary Mills. For ultra-fine grinding results down into the nano range in shorter times.

Your advantage: the shortest grinding times down to any desired fineness, even into the nano range. -

FEATURES

- Rotational speed of main disk 150 – 1100 rpm, relative rotational speed of grinding bowls up to 2200 rpm

- Absolutely safe operation – due to the revolutionary SelfLOCK, grinding bowls snap into place in the machine – without any additional clamping

- Blocking of the mill in the event of impermissible operating states

- Automatic shutoff function if an imbalance occurs

- Prevention of impermissible grinding settings due to automatic detection of inserted grinding bowls and optimisation of rotation speed via RFID-Chip

- Automatic parameter check before each grinding guarantees exact reproducibility

- Added time savings and reliability due to fast bowl changes

- Simultaneous comminution of up to 2 samples

- Useful capacity of up to 2 x 30 ml

- Ergonomically designed touchscreen features a particularly logical menu structure in 10 languages for easy, intuitive user navigation

- Extensive accessories for simplifying your daily work

-

FASTER – SIMPLER – SAFER

Fast, simple and safe operation

The sunken bowls with SelfLOCK Technology form a single unit with the lid – no additional tensioning, no incorrect operation! The bowls are simply placed in the mill, where they position themselves and snap securely into place. The grinding chamber of the premium line opens and closes automatically and independently rotates the bowl mountings into a convenient position for handling. Removal and opening of the bowls are also performed with just two motions. For easy cleaning even the milling chamber cover can be completely removed.

-

SOFTWARE MillControl - EASY GTM

Automatic control and monitoring – Measurement of gas pressure and temperature

The software MillControl enables the automatic control of the Planetary Micro Mill PULVERISETTE 7 premium line and validation of the grinding process. The actual rotational speed and power consumption are checked and documented. By using two EASY GTM-bowls with special lid and transmitter you transform your PULVERISETTE 7 premium line into an analytical measuring system for monitoring pressure and temperature during the grinding process.

-

EQUIPMENT / ACCESSORIES

Configure your Planetary Micro Mill PULVERISETTE 7 premium line exactly to your specific application

The Planetary Micro Mill PULVERISETTE 7 premium line operates with two grinding bowls in the sizes 20 ml, 45 ml or 80 ml, which turn with a transmission ratio of 1 : –2 relative to the main disk. To achieve the best grinding results and for direct prevention of contamination of the samples due to undesired abrasion, all grinding bowls and balls are available in 6 different materials. For grinding in inert gas and for mechanical activation and alloying premium line gassing lids are recommended – quickly and safely. For grinding in suspension, we offer an Emptying Device for a quick and easy separation of the grinding balls and suspension.

-

Applications / Solutions

-

In this white paper Robert lonescu, Isaac Ruiz, Chueh Liu, and Matthew Garrity from the Materials Research Lab Of Ionbell show how our Ball Mills have enabled lonobell to rapid prototype through a variety of silicon particle geometries to produce the next generation of high-capacity silicon-based lithium-ion batteries.

-

The importance of milling for 3D printing

When it comes to 3D printing, the principle from the large to the small is reversed. In previous, well-known manufacturing processes, a component is created by removing material, for example by means of CNC turning or milling. In additive manufacturing, the approach is virtually reversed. Here, the part previously designed in CAD is created from a powder or a liquid by means of a 3D printing process.

-

Grinding glass into the nano range

Ground glass in the sub-micro range has properties of non-Newtonian fluids (rheopexy). In order to penetrate into the nano range, high-performance mills such as the Planetary Micro Mill PULVERISETTE 7 premium line must be used.

-

Mixing two samples with a FRITSCH Planetary Mill

Learn more about mixing white aluminum oxide and red pigments in an 80 ml agate grinding bowl with approx. 250 agate grinding balls 5 mm dia. in less than 90 seconds.

-

Milling tests with the Fritsch Planetary Ball Mill

Our application consultant Diels Ding, German Centre Singapore, comminutes mineral fertilizer down to nanoparticles.

-

Rock, Paper, Scissors: Ways that Milling and Sample Prep Affect Our Everyday Lives

Find out what the children’s game “Rock, Paper, Scissors” has to do with the science of milling and sample preparation.

-

Micromilling of uniform nanoparticles

Fritsch micromills have enhanced one NASA lab’s ability to develop optimized ceramic nanoparticulate materials for demanding research projects, including energy storage and thermoelectric device applications, written by Curtis W. Hill und Lee Allen, NASA Marshall Space Flight Center.

-

Influence of properties of grinding bowls in the planetary system

A clean and constant wear on the inner grinding bowl surface is a question of the amount of grinding balls and size, material amount and size (coarse or fine), the grinding condition like wet or dry grinding, the grinding duration and the adjusted rotations of the planetary system.

-

From “Boulder” to Nano-Particles

Medium-hard to hard materials with edge lengths up to 95 mm can be pre-crushed with the FRITSCH Jaw Crusher PULVERISETTE 1 so an additional fine comminution with many FRITSCH mills is possible.

-

Creation of Nano-Powders

FRITSCH GmbH successfully launched and established the new planetary ball mill PULVERISETTE 7 premium line. With this comminution concept FRITSCH considers customer needs wanting to comminute small samples up into the nano-range (1nm = 10-9m).

-

The Quantum Leap into the Nano Class

Planetary ball mills have long been a popular tool for the finest comminution of powders down to the micrometer range. In many industry segments, however, this is no longer sufficient. Demand now exists for the creation of nano particles (1nm = 10-9m).

-

Planetary Ball Mills as an instrument in mechanochemistry

One of the most significant fields of application for FRITSCH Planetary Mills is mechanochemistry. This subject is in theory, as well as in practice very wide-ranging and versatile. In the article you will find summarized information about history, functionality and the fields of application of mechanochemistry.

-

Speed-up your synthesis lab: Planetary Ball Mills as a tool in organic synthesis

Global problems such as energy and raw material shortages are also an important matter for organic synthesis laboratories. New methods and improved synthetic strategies are developed by the Institute for Technical Chemistry and Environmental Chemistry in Jena with Planetary Mills.

-

Characteristics of sand and criteria for its comminution

Sand is a common unconsolidated sedimentary rock. The mineral composition varies. The analytical evaluation of the chemical composition and therefore the aptness for the intended uses make the comminution of quartz sand a prerequisite. With FRITSCH instruments, the tracking and optimization of the comminution processes can be excellently accomplished.

-

Grinding teas – herbal tea, black tea or green tea

An efficient sample preparation for fast, reliable and reproducible analyses results is becoming nowadays increasingly more important. Especially in the food industry is an exact sample preparation as a prerequisite for fine analyses essential, in order to be able to comply with specified limit and tolerance values.

-

Vanadium – a metal with unlimited fields of application

Vanadium – a transition metal with special potential. An interesting topic which for example is broadened through the possible uses of vanadium in the energy transition. In this article, the material properties of vanadium are discussed and the sample preparation described.

-

Comminution of Pills

The determination of substances contained in tablets after the production process is mandated according to the analytical rules of the German and European Pharmacopoeia. These rules include an analysis in regards to quality, effectiveness and safety of all contained active components and auxiliary materials.

-