Back to overview

Creation of Nano-Powders

FRITSCH GmbH successfully launched and established the new Planetary Ball Mill PULVERISETTE 7 premium line. With this comminution concept FRITSCH considers customer needs wanting to comminute small samples up into the nano-range (1 nm = 10-9 m).

So for example, the pharmaceutical industry is interested in the production of new medications with active ingredients in the nano scale. Active ingredients in the nano scale are absorbed by the human body much faster as conventional compounds; due to the better bioavailability it is possible to clearly reduce the dosage of medications. Despite less amounts of active ingredients the same therapeutic effects are achieved, but at the same time unwanted side effects are reduced. In the chemical industry nano particles are also demanded, since their enormously enlarged specific surface, demonstrate completely new catalytic attributes.

Principle of the planetary mills

In a planetary mill, the sample is placed inside a grinding bowl along with the grinding balls. The grinding bowls are fastened onto the so called sun dial and counter rotate around the centre of this disk. By beating, crushing and grinding, the sample is effectively comminuted. The maximum possible speed range for conventional planetary mills is limited and is approximately 800 rpm. The decisive difference of the premium line to a regular mill is the clamping of the grinding bowls. Instead of clamping them onto the sun disk, the bowls are sunken into it (SelfLOCK Technology).

This now allows a maximum rotational speed inside the premium lime of 1100 rpm and therefore the increase of the kinetic energy of the grinding bodies by 150%. The grinding duration into the nano scale also is drastically reduced respectively makes the comminution of nano particles for certain materials possible in the first place.

Nano grinding of aluminium oxide

As a testing system we here present the comminution of aluminium oxide (Al2O3). The d50 value of the base material is 20 µm. 5 ml Al2O3 and along with water and 0.5 mm zirconium oxide balls are in 60 minutes ground down to approximately 300 nm. In order to reach the range of <100 nm, it is necessary to even utilize smaller grinding pearls. We use zirconium oxide pearls with a diameter of 0.1mm.

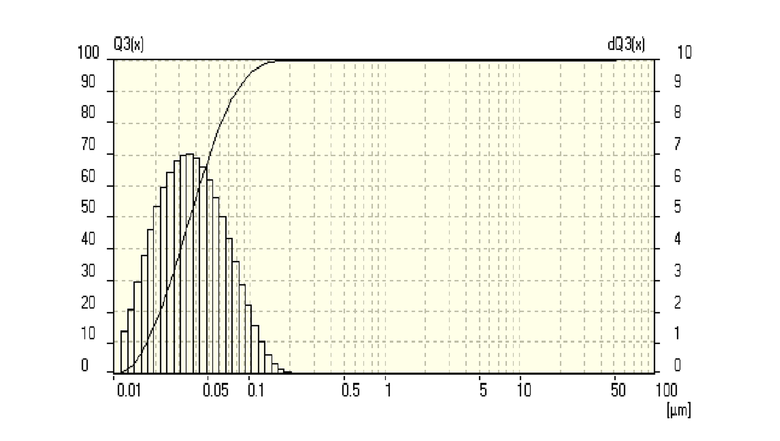

After an additional 180 minutes we obtain the following result:

| d value [%] | grain size [nm] |

| d10 (nm) | 17 |

| d50 (nm) | 32 |

| d90 (nm) | 80 |

The depicted grain size distribution was measured with the FRITSCH Laser Particle Sizer ANALYSETTE 22 in consideration of the corresponding Mie parameters. With a comminution with a ball mill, a certain abrasion on the grinding bodies cannot be avoided. This occurring abrasion in the above measuring was deducted from the original.

Comparable results can also be achieved with other, hard fibrous metal oxides. Here the comminution is always in a suspension. A dry comminution is not possible. Nano particles have a very large specific surface. Therefore the suspension is not stable during the end of the comminution, i.e. the particles re-agglomerate very fast. For the stabilization special additives have to be used. Corresponding tests are performed in our application laboratory.

Additional advantages

The sinking of the grinding bowls with the new SelfLOCK-Technology increases the safety of the process during comminution. With now only two hand motions the bowls are clamped into the mill which improves the process safety during grinding. Faulty operation impossible!

An RFID-chip integrated into the lid of the bowl also automatically identifies the grinding bowls used. The rotation speed is optimized and impermissible grinding settings are prevented. Naturally a balance check is integrated which prevents start up of the mill if it is loaded incorrectly.

The completely newly developed special bowls allow for secure sealing. Any overpressure arising during grinding can be released in a controlled fashion through a built-in valve in the lid. In other words, the best conditions for achieving precise and reproducible grinding results down into the nano range.

For routine operation, the premium line is naturally also capable of generating and saving various grinding programs. The variable parameters are speed, grinding time, pause times and reverse mode. It is possible to generate SOPs (Standard Operating procedures) that can be protected with a password. The premium line has an USB interface for integration into the IT structure of the laboratory. Naturally, all grinding parameters can be recorded and saved by special software. This makes it possible to validate the grinding process.

Accessories for each specific application

Grinding bowl in the sizes 20 ml, 45 ml, and 80 ml are available for the new FRITSCH PULVERISETTE 7 premium line. A series of different bowl materials are available for the widest range of applications, of course. From agate to zirconium oxide, from steel to hard metal tungsten carbide, the right material exists for every application.

In addition, it is possible to select from an entire range of different ball sizes. It should be noted in particular, that increasingly small grinding balls are also required in order to achieve ever smaller particle sizes.

FRITSCH PULVERISETTE 7 premium line - the new standard for the creation of nano powders on a laboratory scale.

-

Download the FRITSCH-report as PDF file

-

Detailed grinding reports

Back to overview