FURTHER PRODUCT GROUPS

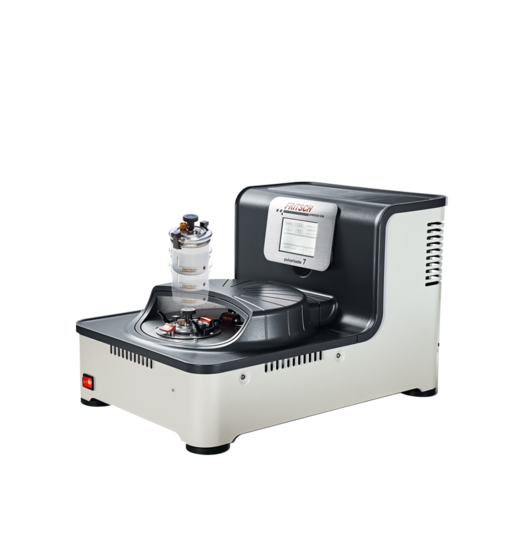

Product details

Technical Data

| Working principle | cutting |

| Optimal for material type | moist, oily, fatty, dry, soft, medium-hard and fibrous |

| Cutting tools | standard knives or sickle knives with 4 blades and sickle knives with serrated blades |

| Materials of the autoclavable cutting tools | knife: stainless steel, TiN-coated grinding vessel: plastic PC, glass, stainless steel 316L, Eastman Tritan Copolyester, Single-use plastic PPlid: silicone, plastic PP, plastic PC |

| Max. feed size (depends on material) | 40 mm |

| Feed quantity (depends on material) | < 1,400 ml 540 ml with the Vario-Lid system |

| Final fineness (depends on material) | < 300 µm |

| Average grinding time | 30 sec |

| Variable speed settings | 2,000 – 10,000 rpm, turbo-function with 14,000 rpm for max. 6 sec. |

| Max. knife peripheral speed | ~ 67 m/s |

| Max. knife diameter | 128 mm |

| Operation modes | continuous, reverse and interval mode |

| USB interface for SOP Management | 20 SOP’s can be saved, generation of grinding reports |

| Motor power | 1250 Watt |

| Electrical details | 200 – 240 V/1~, 50/60 Hz, 1250 Watt |

| Instrument also available in the following voltage | 100 – 120 V/1~, 50/60 Hz, 1000 Watt order no. 11.3010.00 |

| Emission sound pressure level at the workplace according to DIN EN ISO 3746 (depending on the material to be ground, selected rotational speed and instrument configuration) | LpAd = 71 dB |

| Weight | 18 kg |

| Dimensions (W x D x H) | bench top instrument 32 x 43 x 48 cm |