Further Rotor / Beater Mills

FURTHER PRODUCT GROUPS

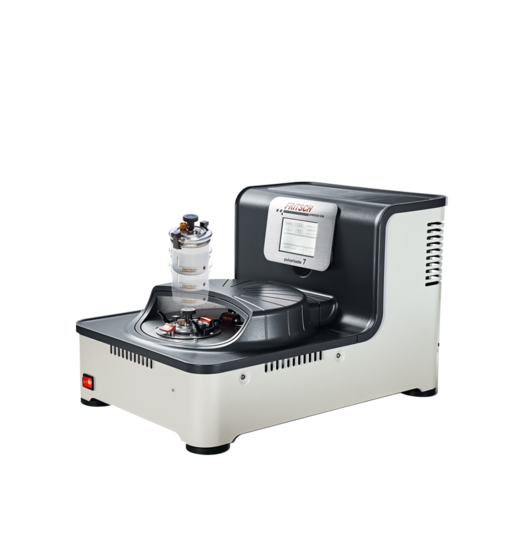

Rotor Mill

P-14

Product details

Technical Data

| Working principle | impact, shearing, cutting |

| Optimal for material type | soft, medium-hard, brittle, tough, elastic, fibrous, temperature-sensitive |

| Grinding tools | impact rotor, impact bar and sieve rings, cutting rotor and sieve shells |

| Materials of the grinding tools | stainless steel, stainless steel 316L, pure titanium grade 2, cutting rotor hardened stainless steel with tungsten carbide; TiN-coated and zirconium edges and titan. |

| Min. sample quantity (depends on sample material) | < 10 ml |

| Max. feed size | 15 mm |

| Final fineness | d50 < 40 μm |

| Rotational speed | Impact: 6,000 - 24,000 rpm Cutting rotor: 2,000 - 18,000 rpm |

| Peripheral speed | Impact rotor: 10.2 m/s – 121.9 m/s Cutting rotor: 8.8 m/s – 79.2 m/s |

| Feeding | batchwise or continuous grinding with FRITSCH Cyclone separators |

| Sample throughput (depending on the material and sieve size) | up to 15 l h and more |

| Electrical details, additional voltages available upon request | 200-240 V/1~, 50-60 Hz |

| Drive power | 2500 Watt |

| Power consumption | 2700 VA (200..240 V) |

| Protection class | IP 22 |

| Emission sound pressure level at the workplace according to DIN EN ISO 3746 (depending on the material to be ground, adjusted rotor-speed and instrument configuration) | approx. LpAd = 82 dB |

| Weight | 33 kg |

| Dimensions (W x D x H) | bench top instrument 42 x 52 x 45 cm |

| Norm standards | CE, UKCA, UL/CSA |