Back to overview

Production of mixtures on a laboratory scale - often a challenge

Probably one of the most difficult tasks was the fine distribution of pure liquid mercury in a mixture of fine solid metal powders. Already during the manual mixing with a spatula, with careless work methods without a problem up to 3 mm large amalgam grains were produced. The solution was added to the Mortar Grinder PULVERISETTE 2, with an agate grinding set and special adjustments for the minimizing of the application of energy found.

From the area of mixtures liquid – solid is the production of filled pastes to be mentioned. Especially challenging here is to add as much as possible solids in the high viscosity organic phase. An additional example for this is, when one has to add to organic binder (for example synthetic resin or varnish or in the simplest case oil) fine metallic, ceramic or inorganic powders. High viscosity pastes evolve which can be compared with shoe polish in a tube. Experts often talk about filled composite materials. Often the increase of the degree of the solid content is the goal of all activities.

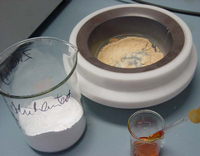

In this concrete case, a metallic powder was to be added to a synthetic resin of high viscosity. Chosen was the Mortar Grinder PULVERISETTE 2, equipped with a grinding set of hardened steel. With processing times of up to 30 minutes, the successive addition of the powder and supported by the slight warming from the applied comminution energy, up to 80% of the mass percentage of the solid was homogenously mixed in.

From the areas of mixtures solid – liquid the contamination of ceramic powders with very little amounts of solved in liquid substances are to be mentioned.

For the test the Mortar Grinder PULVERISETTE 2 with an agate grinding set was chosen. The iron nitrate solution was used as the model-solution since it is coloured and therefore the homogeneity of the mixture was very easily visually evaluated. While the mill was grinding, approximately 1 ml liquid in 50 g powder were instilled. Afterwards it was further homogenized.

-

Download the FRITSCH-report as PDF file

-

Detailed grinding reports

Back to overview