Back to overview

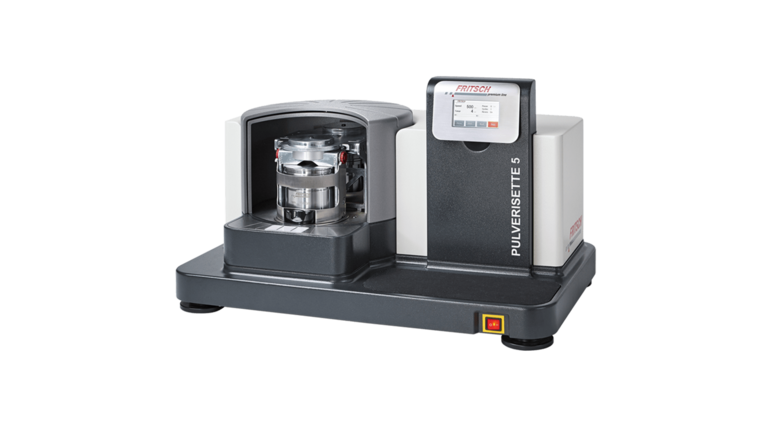

FRITSCH Planetary Mill PULVERISETTE 5 premium line

A quantum leap into the nano range – now also for larger sample quantities

In the year 2006, FRITSCH GmbH first presented the Planetary Micro Mill PULVERISETTE 7 premium line. This high-energy planetary ball mill revolutionised the production of finest particle sizes down to the nanometer range due to previously unachieved rotational speeds of 1100 rpm and a correspondingly high energy application. Since then, the PULVERISETTE 7 premium line has become an indispensable instrument for mechanical alloying, research into new fuel cells and the development of lithium-ion batteries. The sample volume permitted by this instrument is relatively small, however, resulting in high demand for a mill with the same performance but a larger volume.

During ACHEMA 2012, FRITSCH GmbH premiered the new Planetary Mill PULVERISETTE 5 premium line, which perfectly meets customer demands.

Planetary Ball Mills

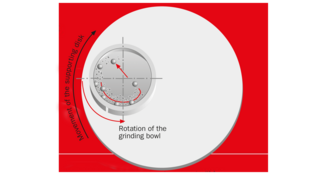

Planetary ball mills are perhaps the most commonly used ball mills in laboratories for the sample preparing of soft to hard, brittle and fibrous materials. The name of this mill type derives from its unique kinematics: the grinding bowls, which are mounted on the rotating sun disk, rotate in the opposite direction around the centre of this disk. Due to this movement, the sample is very effectively and quickly comminuted by impact, shearing and friction forces resulting from ball-to-ball and ball-to-wall collisions.

With the planetary movement, the grinding bowl filling is subject not only to the force of gravity, as in the case with conventional ball mills, but centrifugal and coriolis forces further increase the kinetic energy of the grinding parts up to 100 times the force of gravity. At high rotational speeds, the effect of these forces on the grinding parts and the material being ground produces a great load intensity and grinding performance. The energy transmission density is roughly 10 times that of vibratory mills and 50 times of conventional ball mills3. The grinding result is influenced by many different parameters, especially by the rotational speed of the mill, the grinding time, the ball size, the ratio of the sample quantity to the ball filling as well as the material of the grinding parts.

Grinding into the Nano Range

The demand for fine particles with a defined size distribution is constantly increasing, especially in the chemical and pharmaceutical industries. The production of finest particles down into the nanometre range can take place either via chemical synthesis, i.e. by generating the particles through crystallisation (bottom-up) or via comminution of already existing coarse particles in a mill (top-down). However, even the particles obtained through crystallisation are often too coarse and require subsequent processing in mills. Industry interest in nano-particles can be explained by the fact that such particles demonstrate completely new physical and chemical properties due to their large specific surface (ratio of surface to volume). For instance, non-conductive materials suddenly become conductors and metal oxides that are actually opaque become transparent4, 5.

Premium Performance

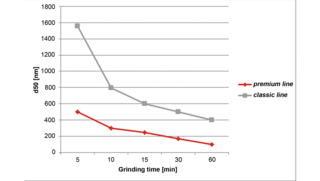

Compared with the previous model PULVERISETTE 5 classic line, the drive power was doubled for the premium line version. The powerful 1.5 kW motor enables a maximum rotational speed of up to 800 rpm, resulting in a significantly increased energy application. As proof of the mill’s performance, a sample of aluminium oxide ground to particles down into the nano range is shown here:

Premium Functionality

In addition to the significantly increased drive power, the operation of the mill is also ‘premium’: All key parameters, such as rotational speed, grinding time, pause function, number of grinding cycles, etc. are entered via a 4.3-inch touch screen with colour display and can be saved as a grinding program.

Until now, for planetary mills with one working station the user had to manually adjust the required compensation for imbalance with a counterweight. With the new FRITSCH PULVERISETTE 5 premium line, the imbalance compensation is performed fully automatic – thanks to another brilliant patent by FRITSCH! Also patented is the new grinding bowl clamping mechanism ServoLOCK. No more spindles or screws and instead with more or less effort clamping the bowls into place now simply: lower ServoLOCK handle – CLICK – finished! Thanks to the motor-driven clamping ServoLOCK, the bowl is reproducibly tensioned with a clamping force of 16 kN [~ 1.6 t]. Premium safety, premium fast and premium simple!

Conclusion

The unique functions of the Planetary Mill PULVERISETTE 5 premium line:

- Doubled drive power for fast, powerful, high-performance grinding

- Fully automatic grinding bowl imbalance compensation

- Motor-driven grinding bowl clamping (ServoLOCK)

- Convenient touch screen with colour display

These features make the new Planetary Mill to another worthy member of the FRITSCH premium line family.

FRITSCH premium line – the new high-tech standard for the modern laboratory.

-

Download the FRITSCH-report as PDF file

The solution for grinding down to the nano range: the NEW Planetary Mill PULVERISETTE 5 premium line

-

Detailed grinding reports

-

Sources and continuative literature

[1] GIT Labor-Fachzeitschrift 10/2007 [2] eine Mahlstation

[2] Höffl, K. (1986). Zerkleinerungs- und Klassiermaschinen, Springer, Berlin

[3] T. Sakai et al, Journal of the Ceramic Society of Japan, 120, 39-41 (2012)

[4] S. Breitung-Faes, A. Kwade, Powder Technology 212 [3], 383-389 (2011)

Back to overview