Virtual Product Presentation

With the virtual product presentation you can experience our particle sizers for automatic particle size and shape analysis directly at your workplace.

Particle Sizer ANALYSETTE 22 NeXT – automatic particle size analysis unbeatably simple

Our two models of the ANALYSETTE 22 NeXT are ideal for efficient particle size analysis in production and quality control as well as in research and development or for controlling manufacturing processes.

Both Particle Sizers differ in design and measuring range.

The ANALYSETTE 22 NeXT Micro, which is reduced to one light source and one detector, measures robustly and reliably from 0.5 to 1500 μm.

The ANALYSETTE 22 NeXT Nano expands the lower measurement value by the intelligent arrangement of an additional detector system. This makes the recording of even larger scattering angles down to 0.01 μm possible in sideward as well as backward direction. The upper measurement limit is increased at the same time to outstanding 3800 μm.

Get all the decisive advantages with the model that meets your requirements: especially easy operation and cleaning, short analysis times, reliably reproducible results and the recording of additional parameters such as temperature and pH value during wet dispersion.

The ANALYSETTE 22 NeXT is developed according to a smart, modular concept. You only buy what you really need. Therefore you can flexibly grow with your sizing tasks. Modules can be added to at any time, and we are constantly developing our portfolio. State-of-the-art technology at an unbeatable price. Cleverly made!

Choose according to your requirements

MODULES ANALYSETTE 22

FURTHER PARTICLE SIZERS

Laser Particle Sizer

ANALYSETTE 22

NeXT NanoTechnical data - Measuring Unit

| Measuring range | 0.01 - 3800 µm |

| Analysis method | Static light scattering (laser diffraction) |

| Type of analysis | Wet measurement of the particle size of solids, suspensions and emulsions |

| Measurement value | Particle size |

| Theory | Fraunhofer, Mie |

| Standard | ISO 13320 |

| Optical design | Reverse Fourier design |

| Laser | Green (λ = 520 nm) |

| Laser beam alignment | Automatic |

| Laser class according to IEC 60825-1 | Class 1 |

| Detector | Specially designed semi-conductor detector |

| Large angle detectors | Yes |

| Backward scattering channels | Yes |

| Typical measuring time | 5 – 10 s (measurement value recording of an individual measurement)1 min (entire measurement cycle) |

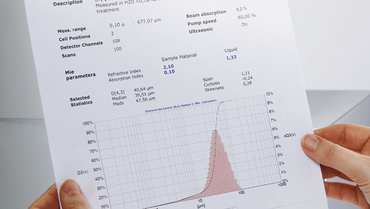

| Evaluation | Particle size distribution as a total curve, bar chart or in table form |

| Electrical details | 100-240 V/1~, 50-60 Hz, 120 Watt |

| Net weight | 21.8 kg |

| Dimensions (w x d x h) | 67 x 35 x 32 cm |

| Software | MaS control / NextControl software for controlling, recording and evaluating the measuring results pre-installed on supplied computer, incl. monitor, keyboard and mouse(without computer hardware for deliveries to CIS countries) |

| System requirements (for computers supplied by customer) | Standard Windows PC, 4 GB RAM, at least Windows 10, USB port, monitor, keyboard, mouse |

Wet Dispersion Unit

| Type of wet dispersion | Closed liquid circulation system |

| Suspension volume | 150 – 500 ml, variable |

| Radial pump | With adjustable speed 3.5 l/min |

| Materials used in the sample circulation system | High-quality stainless steel 316L, PTFE, FFKM , FEP, BK7 glass, FKM , hoses made of silicone |

| Conversion kit Extended for extreme chemical resistance (optional) | Seals made of FFKM, flow plate made of PTFE, hoses with inner liner made of FEP |

| Sample material characteristics | Suspensions, emulsions and solids that do not agglomerate, are not soluble in the dispersion liquids or are poorly free-flowing or are sticky |

| Sample quantity | Some 10 mg (μm range) to a few grams (mm range) depending on the sample material and particle size |

| Net weight | 16 kg |

| Dimensions (w x d x h) | 24.6 x 24.6 x 30 cm |

Ultrasonic Box

| Output | Adjustable up to 50 Watt |

| Materials used in the sample circulation system | High-quality stainless steel 316L, FFKM, hoses made of silicone |

| Sample material characteristics | Suspensions, emulsions and solids that agglomerate |

| Net weight | 6.2 kg |

| Dimensions (w x d x h) | 28.7 x 9 x 27.9 cm |

Dry Dispersion Unit

| Type of dry dispersion | Measurement of powdery samples in an accelerated airflow, degradation of agglomerates with compressed air |

| Sample material characteristics | Not too fine, free-flowing materials, which react in water or other liquids |

| Sample volume | 1 – 300 cm3 |

| Sample feeding | high-frequency feeder |

| Dispersion | Venturi nozzle |

| Required compressed air supply | min. 5 bar, 125 l/min, oil-free, water-free, particle-free |

| Sample exhaust | external exhaust system required |

| Net weight | 18.1 kg |

| Dimensions (W x D x H) | 22 x 39 x 38 cm |

Downloads

Product Profile A-22

Product leaflet A-22

Webinar Measurement of particle size distribution using laser diffraction

Watch Video