Many samples - due to their material characteristics - require a special preparation for the measurement. For example can static charges (for example plastics), adhesion forces or cohesive forces (for example clays, soil samples, kaolins), magnetism and hydrophobic characteristics (for example pharmaceutical products, drugs, toner, graphite, titanium oxide) or coagulation (for example clays, kaolins, chalk and gypsum), complicate the dispersion and measurement.

When dispersion is necessary in order to measure the primary particles, the wet dispersion represents the ideal method for most samples.

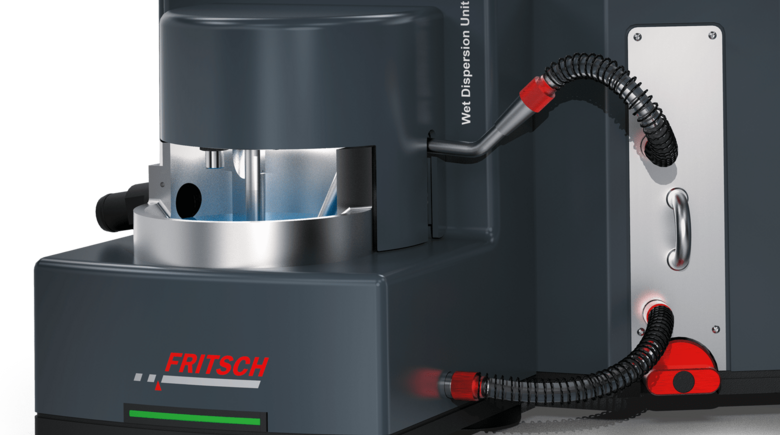

Wet dispersion

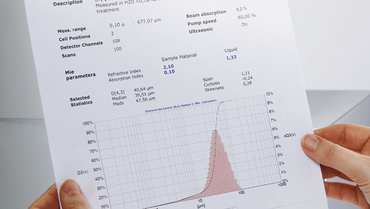

During a wet dispersion the sample material is added to a closed liquid circuit and continuously pumped through the measurement cell. During the pumping process in the measuring circuit, ultrasound can be added in order to break up the agglomerates and obtaining single and separated particles. Unproblematic samples that submerse directly in water without significant effort and do not have large fines, are added to the dispersing unit of the ANALYSETTE 22 as a solid, portion by portion, using a spatula and can be measured reproducibly after a brief ultrasound exposure / dispersion (30 - 60 s). Prior to a measurement, especially for strongly bonded agglomerates, a treatment of the sample, with ultrasound is often helpful. For the wet dispersion, if possible should the selected liquid wet the material spontaneously and completely.

-

Detailed dispersion tips

Sample preparation for the Laser Particle Sizer ANALYSETTE 22

-

Instrument-Recommendation

FRITSCH-Know-How – For an exact measurement should:

- Solids be separated and free of agglomerates

- During the entire measurement the dispersion condition should be stable, without coagulation or flocculation

- Floating particles on the liquids surface should be avoided

- The sample should not be destroyed respectively comminuted during the dispersion

- Ideally, the carrier liquid should have a lower density than the solid