textile

| M210001 | |

| Plastics / textiles, Environment | |

| 45.0 cm | |

| 100.0 % < 15.0 cm | |

| 12.0 kg | |

| We recommend using our Universal Cutting Mill PULVERISETTE 19 with a 2 mm square perforated sieve cassette in combination with our high-performance cyclone separator. For the textile sample and for the FFP 2 masks a 4 mm square sieve cassette and a 3 liter vessel. |

|

|

Universal Cutting Mill PULVERISETTE 19 Speed 300-3000 rpmspeed: 3000 revolutions per minute |

|

| Equipment: |

rotor: Standard rotor with V-cutting edges optional accessories: High-performance cyclone separator material: Hardened stainless steel sieve cassette: 2 mm square perforation |

|

|

|

105 g | |

|

|

length 80 mm | |

|

|

2 min | |

|

|

< 2 mm | |

|

|

In this trial we used our Universal Cutting Mill PULVERISETTE 19 with a 2 mm square perforated sieve cassette and our high-performance cyclone separator. The machine speed was set the maximum of 3000 rpm.

We used 100 g of the pre-ground textile as a batch. The sample was fed piecewise and was ground within 2 minutes. The grinding sound was typical. By using our high-performance cyclone with sample exhaust, the grinding chamber and sample were better cooled and transferred to a collecting vessel.

The cleaning was performed with a vacuum cleaner and a brush.

|

|

| Pictures: | Original size of the sample. |

|

| Pre-ground sample. |

|

|

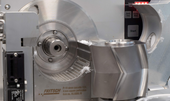

| Open grinding chamber after a grinding time of 2 minutes. |

|

|

| Ground sample with a 2 mm square perforated sieve cassette. |

|

|

|

|

Universal Cutting Mill PULVERISETTE 19 Speed 300-3000 rpmspeed: 3000 revolutions per minute |

|

| Equipment: |

rotor: Standard rotor with V-cutting edges optional accessories: Collecting vessel 3 liter volume material: Hardened stainless steel sieve cassette: 4 mm square perforation |

|

|

|

length 10 g | |

|

|

150 mm | |

|

|

45 seconds | |

|

|

< 4 mm | |

|

|

In this trial we used our Universal Cutting Mill PULVERISETTE 19 with a 4 mm square perforated sieve cassette and a 3 liter collecting vessel. The machine setting was set to the maximum of 3000 rpm.

We used 2 FFP 2 masks (~10 g) as a batch. The masks were fed and ground piecewise within 45 seconds. The grinding sound was typical. Afterwards we checked the grinding chamber. Only a few sample residues were found.

The cleaning was performed with a vacuum cleaner and a brush.

|

|

| Pictures: | Original size of the FFP 2 mask. |

|

| Open grinding chamber after a grinding time of 45 seconds. |

|

|

| Ground FFP 2 mask after a grinding time of 45 seconds. |

|

|

FRITSCH GmbH - Milling and Sizing

55743 Idar-Oberstein