Back to overview

Sample preparation in the ceramics industry

Assurance of quality and process standards

Based on the risen quality standards more and more often the crude materials and also the finished products are more precisely analyzed. Considered are the classic chemical and physical variables as well as the technological data of crude materials and finished parts like for example:

- Geochemical and mineralogical composition

- Thermal shock resistance

- Thermal conductivity & coefficient of thermal expansion

- Breaking resistance & flexural strength

Based on the very inhomogeneous composition of clays, which are mostly composed of various clay minerals, a sample preparation in a clay and ceramics laboratory for further analytical use via x-ray fluorescence, atomic absorption spectrometer, or inductively coupled plasma emission spectrometry, or AES is mandatory since the chemical composition of the crude materials has a decisive influence on the technical abilities of the finished products.

Due to these facts, one of the leading producers for crude clays, milling clays, chamottes and ceramic masses, the renowned company from the Westerwald Goerg & Schneider, chose the FRITSCH Planetary Mono Mill PULVERISETTE 6 classic line with an agate grinding set, for the efficient and time saving sample preparation.

The main area of utilization of the PULVERISETTE 6 classic line is the fine grinding of milling clays respectively pre-broken pieces of chamottes. The size of the basic sample is between 0.2 - 5 mm.

The finely ground firing clay is needed in order to produce by adding bentonite as a bonding clay, models for the determination of the thermal expansion coefficient. Furthermore, the in this manner obtained sample amount of approximately 100 grams is used for the disintegration of the fusion tablet during the X-ray fluorescence analysis in order to determine the chemical composition of the finished product.

The decision in regards of the selection of the comminution tools, is mainly based on the chemical composition (see element analysis below) as well as in the physical and mechanical characteristics of agate.

Element analysis agate

| Element | Share % |

| Silicone oxide - SiO2 | 99.9 % |

| Aluminium - Al2O3 | < 0.02 % |

| Iron oxide - Fe2O3 | < 0.02 % |

| Calcium oxide - CaO | < 0.02 % |

| Magnesium - MgO | < 0.02 % |

| Sodium carbonate - Na2O | < 0.02 % |

| Potassium carbonate - K2O | < 0,02 % |

| Manganese oxide - MnO | < 0.02 % |

| Physical and mechanical properties | |

| Density | 2.65 g/cm³ |

| Hardness | 6.5 – 7 Mohs |

Due to the considered relative chemical neutrality of the composition (99,9 % SiO2) therefore no other elements from the agate, respectively from the preparation, do not influence at all or only in a limited manner the material characteristics like for example the burn colour, thermal conductivity, or the flexural strength of the finished products. The mohs hardness of the agate with 6.5 -7, is above this also sufficient in order to fulfil the demanded tasks in a qualitative manner of a 100%.

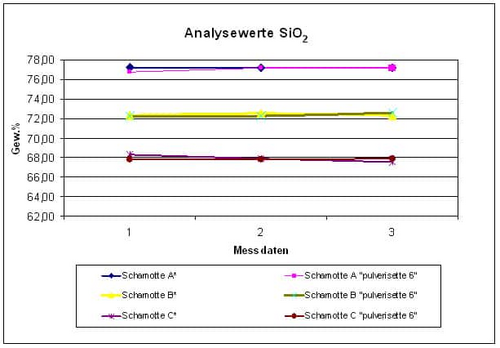

Illustration A shows that the insertion of SiO2 as indicator for the emerging abrasion during mechanical comminution of the agate grinding set, can despite the clearly higher application of energy of the planetary mill compared to the previous preparation with the mortar principle, be almost completely ignored.

An additional very decisive criterion for the purchase of the Planetary Mono Mill PULVERISETTE 6 classic line by FRITSCH, was the efficient preparation and the associated time saving during the sample preparation with this type mill – the planetary mill.

Due to the use of the planetary mill, 90% of time was saved, compared of the previously used mechanical preparation.

-

Download the FRITSCH-report as PDF file

-

Detailed grinding reports

Back to overview