Further Planetary Mills

FURTHER PRODUCT GROUPS

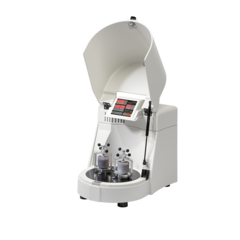

Planetary Mono Mill

PULVERISETTE 6

classic line-

OVERVIEW

High performance in minimum space

The Planetary Mono Mill PULVERISETTE 6 classic line is a high-performance Planetary Ball Mill with a single grinding bowl mount and practical, easily adjustable imbalance compensation. Your advantage: Particularly easy use and high-energy effect of up to 650 rpm. This ensures a constantly high grinding performance with extremely low space requirements for loss-free grinding results for the comminution of hard, medium-hard, brittle and moist materials, dry in suspension or in inert gas.

At same time, the PULVERISETTE 6 classic line is ideally suited for mechanical alloying or for mixing and perfect homogenising of emulsions and pastes. -

WORKING PRINCIPLE

Comminution according to the Planetary Principle

The comminution of the material to be ground takes place primarily through the high-energy impact of grinding balls. To achieve this, the grinding bowl, containing the material to be ground and grinding balls, rotates around its own axis on a main disk whilst rotating rapidly in the opposite direction. At a certain speed, the centrifugal force causes the ground sample material and grinding balls to separate from the inner wall of the grinding bowl. The grinding balls then cross the bowl at high speed and further grind the sample material by impact against the opposite bowl wall. In addition, impact between the balls themselves on the sample material adds to the size reduction process.

Due to the enormous rotational speed of the main disk – up to 650 rpm – achieves the PULVERISETTE 6 classic line a centrifugal acceleration of up to 29 g. -

FEATURES

- Special grinding force due to a rotational speed of up to 650 rpm

- Low space requirements and ergonomic design

- Particularly easy-to-use

- Timer programming precise to ± one second

- Simultaneous processing of up to 2 samples

- Useful capacity up to 225 ml

- Large rotational speed range with accurate display

- Easy to open grinding chamber completely encapsulated

- Cooling of the grinding chamber with a built-in fan for long grinding times

- Exactly reproducible grinding results thanks to a regulated drive, precise transmission ratio (toothed belt), programmable microprocessor control electronic

- Programmable interval and pause times

- Smaller grinding bowls also possible with an adapter

- Monitoring of the grinding parameters even when grinding chamber is open through an ergonomically positioned and always visible, splash-proof IP65 membrane keyboard

- Easy cleaning of the grinding elements

- Energy-save-function (electricity-saving mode)

- Extensive accessories for simplifying your daily work

View extensive accessories

-

SAFE GRINDING BOWL CLAMPING

Reproducible grinding results and absolutely safe grinding bowl clamping

Especially convenient for exact, reproducibility and grinding of smallest sample amounts is the electronic timer: adjustable to the second and a programmable reversing feature. The Safe-Lock System, which is delivered with a torque wrench, enables simple and safe clamping of the grinding bowls - absolutely risk-free.

-

MEASURING GAS PRESSURE AND TEMPERATURE

EASY GTM classic line - Gas Pressure and Temperature Measuring System

With the new EASY GTM Gas Pressure and Temperature Measuring System you can turn the Planetary Mono Mill PULVERISETTE 6 classic line into an analytical measurement system.

-

EQUIPMENT / ACCESSORIES

Configure your Planetary Mono Mill PULVERISETTE 6 classic line exactly to your specific application

The Planetary Mono Mill PULVERISETTE 6 classic line with 1 working station operates with 1 respectively 2 grinding bowls of sizes 80, 250, 500 ml, which turn with a transmission ratio 1 : -1,82 relative to the main disk. To achieve best grinding results and for direct prevention of contamination of the samples due to undesired abrasion, grinding bowls and grinding balls are available in 6 different materials.

For grinding in inert gas, for mechanical activation and alloying are gassing lids recommended.

-

Applications / Solutions

-

Learn more about mixing white aluminum oxide and red pigments in an 80 ml agate grinding bowl with approx. 250 agate grinding balls 5 mm dia. in less than 90 seconds.

-

Milling a rock sample with the Planetary Mono Mill PULVERISETTE 6 classic line

Learn more about dry and wet grinding of a rock sample using an 80 ml agate grinding bowl with 5 agate grinding balls 20 mm dia. and afterwards with approx. 250 agate grinding balls 5 mm dia.

-

Rock, Paper, Scissors: Ways that Milling and Sample Prep Affect Our Everyday Lives

Find out what the children’s game “Rock, Paper, Scissors” has to do with the science of milling and sample preparation.

-

Influence of properties of grinding bowls in the planetary system

A clean and constant wear on the inner grinding bowl surface is a question of the amount of grinding balls and size, material amount and size (coarse or fine), the grinding condition like wet or dry grinding, the grinding duration and the adjusted rotations of the planetary system.

-

From “Boulder” to Nano-Particles

Medium-hard to hard materials with edge lengths up to 95 mm can be pre-crushed with the FRITSCH Jaw Crusher PULVERISETTE 1 so an additional fine comminution with many FRITSCH mills is possible.

-

InSitu Acquisition of Grinding Parameters

In the laboratory sector planetary ball mills are usually utilised to reduce the size of a broad range of samples in batches at high energy.

-

Additives for dry milling

During a dry grinding, often only after a short grinding period hygroscopic material tends to stick. A second factor causing this is the static charge respectively adhesive powers of fine particles.

-

Bacteria, a new challenge for Planetary Mills

Planetary Mills offer the perfect mechanical decomposition methods when processing bacteria.

-

Crushing concrete coarsely and fine

Concrete is a complex material, which its characteristics due to its composition and as a result of the systematic addition of additives can be adjusted very differentiated. However, this results in the demand to monitor this composition for two reasons: in order to ensure the desired useful properties and also to ensure the quality of the mixture.

-

Sample preparation in the ceramics industry

Clays, chamottes and ceramics are used versatile and must therefore be in accordance with different degrees of quality standards. These quality standards have especially in recent years gained in significance for the processing industry and therefore at the same time for the producers of such chamottes and ceramics.

-

Processing selenium in the laboratory

Selenium – listed in the periodic system of the elements in the 6th main group, below sulphur, is unknown to many. Although it belongs to the essential trace elements and is integrated by the body in the so called 21st amino acid. But still, it’s a toxin and the comminution of it requires a certain caution.

-

Planetary Ball Mills as an instrument in mechanochemistry

One of the most significant fields of application for FRITSCH Planetary Mills is mechanochemistry. This subject is in theory, as well as in practice very wide-ranging and versatile. In the article you will find summarized information about history, functionality and the fields of application of mechanochemistry.

-

Nanoscale materials for hydrogen storage

The production of nano materials for the storage of hydrogen. A film by the Karlsruhe Institute of Technology - only available in German.

-

Processing silage for biogas

New ideas are necessary for the production of renewable energy sources and for the sample preparation a Planetary Ball Mill.

-

Characteristics of sand and criteria for its comminution

Sand is a common unconsolidated sedimentary rock. The mineral composition varies. The analytical evaluation of the chemical composition and therefore the aptness for the intended uses make the comminution of quartz sand a prerequisite. With FRITSCH instruments, the tracking and optimization of the comminution processes can be excellently accomplished.

-

Processing cocoa beans in the laboratory

The most important products which we as consumers come in contact with are cocoa beverages and chocolate. The most important characteristic trait for us is the taste. But before they become chocolate, the cocoa beans have to be roasted, peeled and cracked open.

-

Milling of ductile materials with Planetary Ball Mills

Comminuting ductile materials such as precious metals can be challenging, but can be mastered with FRITSCH Planetary Mills.

-