Further Rotor / Beater Mills

FURTHER PRODUCT GROUPS

Variable Speed Rotor Mill

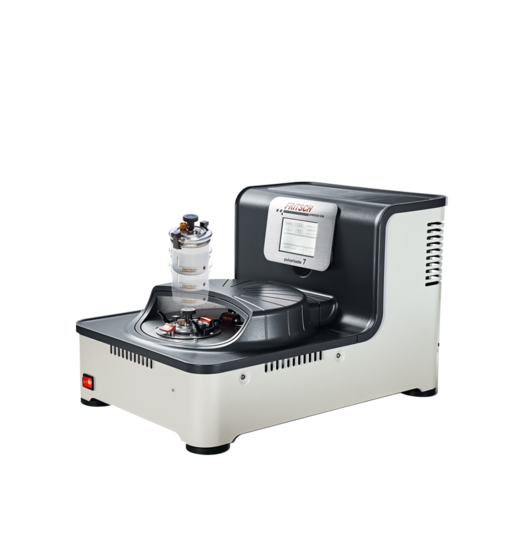

PULVERISETTE 14

classic line-

OVERVIEW

Effective comminution due to highest rotor speed

The FRITSCH Variable Speed Rotor Mill PULVERISETTE 14 classic line is the ideal mill for fast, effective comminution of soft to medium-hard, brittle and fibrous materials as well as temperature-sensitive samples – proven worldwide for the use in trace analysis.

Difficult-to-mill samples, or extremely temperature-sensitive samples such as styrenes, polyester, synthetic resins, films, PVC, PP and PE can be embrittled with the addition of liquid nitrogen and afterwards ground in the PULVERISETTE 14 classic line. The motor speed can be varied between 6,000 and 20,000 rpm in increments of one-thousand - making it possible to adapt the mill to each specific application. An automatic speed compensation feature ensures an ideal adaptation of the grinding to the specific comminution behaviour of the sample. At the same time reduces the fast, effective grinding significantly the thermal strain on the sample.

-

WORKING PRINCIPLE

Impact and shearing

Inside the Variable Speed Rotor Mill PULVERISETTE 14 classic line, the sample is comminuted by impact on the ribs of the rotor rotating at a high speed and additionally sheared between the rotor-teeth and between the utilized sieve ring.

-

FEATURES

- Rapid sample throughput due to high-speed grinding

- Max. feed size 10 mm, max. throughput 5 l/h

- Final fineness d50 < 40 μm, sieve rings 0.08 – 6 mm

- Ideal for minimal sample quantities < 10 ml

- Simple, tool-free changing of rotor, collecting vessel, sieve ring and labyrinth seal

- Simple, contamination-free cleaning and assembly of all grinding parts outside the instrument

- Heavy-metal and iron-free grinding and sample preparation according to RoHS

- Comminution of difficult-to-mill and temperature-sensitive samples – also cryogenic

- Variable speed settings between 6,000 and 20,000 rpm

- Automatic speed regulation for constant milling

- Efficient cooling of the grinding chamber due to extremely high airflow

- Highly durable low-wear rotor made of stainless steel

- Grinding chamber made of stainless steel or PTFE-coated with practical quick-clamping lock

- Grinding parts made of stainless steel, pure titanium and TiN-coated

- Maintenance-free three-phase motor with regulated rotor speed 6,000 - 20,000 rpm

- High speed stability even under full load

- Wear-free labyrinth seal between the grinding chamber and drive motor

- Removable dust filter for convenient cleaning

- Ergonomic operating panel with membrane keyboard and timer

- Microcontroller with integrated regulation function for Vibratory Feeder

- Optimal for fine comminution after pre-crushing with the FRITSCH Cutting Mills

- Temperature gentle fine grinding with the FRITSCH Cyclone separators

- Extensive accessories available – easing your laboratory tasks

-

WORKING FASTER

More powerful frequency converter

With a more powerful frequency converter, the Speed Rotor Mill PULVERISETTE 14 classic line ensures that the motor output is precisely matched to the grinding material.

Your advantage: faster sample feeding, a constant rotational speed and a higher throughput. The well-designed LED display in the ergonomic operating panel with membrane keyboard, displays the speed and motor load and alerts in the event of reaching the temperature limit and overload. -

EFFICIENT COOLING

Ingenious air routing

Available only from FRITSCH: The ingenious air routing of the PULVERISETTE 14 classic line ensures a constant airflow to cool the rotor, all motor components and the grinding material in the collecting vessel. At the same time, a large fan blows the cooling air into the instrument through a foam particle filter to create positive pressure that prevents the penetration of dirt particles from the ambient air.

-

EXCHANGE OF GRINDING TOOLS WITHOUT TOOLS

Fast exchange of all grinding tools - easy cleaning

All grinding parts can be removed without tools with just a few motions – for quickly exchanging all grinding parts and for cleaning them outside of the instrument. The especially smooth surface of the stainless steel impact rotors simplifies a thorough cleaning – fast and easy! The wear-free labyrinth seal between the grinding chamber and the motor offers secure protection against contamination of the instrument.

-

NEW: FRITSCH CYCLONES

NEW: temperature gentle fine grinding with the FRITSCH Cyclone separators

In combination with the FRITSCH Cyclones the Variable Speed Rotor Mill PULVERISETTE 14 classic line is ideal for ultra-fine grinding of temperature-sensitive samples like powder coatings and plastic samples or for smooth pre-crushing and fine grinding of hard-brittle to soft, fatty or samples with residual moisture.

Small volume Cyclone separator: The compact FRITSCH small volume separator completely made of plastic can be dismantled completely and cleaned in the dishwasher thus reliably preventing contaminations. The comminuted sample is collected in a screwed-on sample glass of 250 or 500 ml volume. The small volume Cyclone separator can be combined with the exhaust system, which can be ordered along, or can also be used with the supplied fine-dust filter 80-100 µm for passive utilization.

High-performance Cyclone separator: Especially for the analytical sector and for the food and pharmaceutical industries is the high-performance separator completely made of stainless steel 304 in combination with the exhaust system indispensable. The exhaust system for the operation of the FRITSCH Cyclones may be ordered along.

The result: an especially fast and effective comminution with minimized thermal load with significantly higher throughput and especially fast and easy cleaning. -

EQUIPMENT / ACCESSORIES

Configure your Variable Speed Rotor Mill PULVERISETTE 14 classic line exactly to your specific application

The Centrifugal Mill PULVERISETTE 14 classic line includes a collecting vessel and lid. In order to operate the mill, you must also order a rotor, a sieve ring, an impact bar or a pin insert - allowing you to select your grinding tools according to your specific application! To ensure this, an extensive accessory programme for the PULVERISETTE 14 classic line is available with rotors and sieve rings in various designs and materials, as well as additional accessories. Choose exactly what you need!

For grinding large quantities we recommend the special conversion kit. This allows the comminution of sample quantities of up to 1 litre in a single step without the need to open the grinding chamber and empty the collecting pan during the process.

Combine your PULVERISETTE 14 classic line with the FRITSCH Vibratory Feeder LABORETTE 24 to ensure continuous feeding of the sample during the entire grinding process, even of smallest quantities. Due to a direct connection, the mill automatically matches the sample feeding to its load state at any given moment.

-

Applications / Solutions

-

Solid isolates of CBD may be created as a non-homogenous “cake” of material, or as a mixture of loosely associated granules comprising a wide particle size distribution. Creating material suitable for consumption or subsequent formulation in other products typically requires particle size reduction and/or homogenization.

-

100 years of experience in comminution now also for the Cannabis industry

What happens when you combine a fourth-generation family business, a century of engineering excellence, a 10,000-year-old medical plant, and an industry worth billions?

-

Rock, Paper, Scissors: Ways that Milling and Sample Prep Affect Our Everyday Lives

Find out what the children’s game “Rock, Paper, Scissors” has to do with the science of milling and sample preparation.

-

The significance of drive power for the efficiency of the Variable Speed Rotor Mill

The aim of all comminution is to achieve a certain fineness. During comminution, particles of a starting material are broken to form many smaller particles.

-

New Applications for FRITSCH Laboratory Instruments

The directives 2003/108/EC (WEEE) and 2002/95/EC (RoHS) of the European Union have opened up new applications for FRITSCH Laboratory Equipment.

-

Purple Moor-Grass - Comminution of Molinia Caerulea

Interesting for research are the absolute contents and the ratios of carbon and nitrogen in the plant material. For the determination of these values mostly carbon and nitrogen analyzers are utilized. First, the sample must be ground though.

-

Comminution of silicone rubber

Many industries rely heavily on silicone rubber as a basic material. Effective for the sample preparation of the material are the FRITSCH-Mills.

-

Analytical determination of crude fibre in animal feed

Even animal feed is sold with a declaration about its contents. For quality assurance those substances of contents are continually examined.

-

Sample analysis of maize kernels

Maize kernels, dressed, prepared as seeds, are subject to testing in regards to possible contents of genetically modified organisms (GMO). The necessity arises to test the seeds for possible properties of genetically modified contents.

-

Sample preparation of mineral animal feed

Many various different kinds of animal feed exist which differ in regards to each animal in composition, appearance and analysis. Nevertheless exact guidelines for its contents in regards to minerals, possible additives and unwanted ingredients exist. Essential for each animal feed is though, that the composition has to be inspected.

-

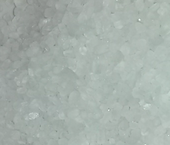

Salt, Sodium Chloride, Potassium Chloride

A prerequisite for an efficient salt extraction and processing is the exact knowledge of the mineral compositions of in-situ evaporates, as well as their chemical composition and also of the accruing intermediate and final products during the manufacturing process.

-

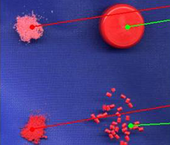

Pigment processing: The isolation of the naturally beautiful

Mankind has always enjoyed enduring works of art. The particles of the pigments have always been playing a major role. For example, the oldest cave paintings still impress us today. One of the most renowned experts for the production of historical pigments is Dr. Kremer from Aichstetten (Bavaria, Germany). FRITSCH laboratory mills are of great importance in Dr. Kremer's pigment processing.

-

Comminution of plastic beverage bottles

While shopping, consumers encounter beverages packaged in plastic (polyethylene terephthalate) bottles. The launching of the new packaging material provision influenced the further purpose of the bottles after their use as packaging. Consumers became aware of this, after the implementation of a deposit and the overall return of all plastic bottles to the stores.

-

Milling of leather for sample preparation

Leather is almost prepared in production facilities and also in testing institutes with cutting mills for analytical monitoring. Perfect for this task are the FRITSCH Cutting Mills.

-

Characterization of polymers

The analysis of polymers is executed with the aid of gel permeability chromatography. Ideal for the sample preparation is the Variable-Speed Rotor Mill PULVERISETTE 14.

-

Grinding teas – herbal tea, black tea or green tea

An efficient sample preparation for fast, reliable and reproducible analyses results is becoming nowadays increasingly more important. Especially in the food industry is an exact sample preparation as a prerequisite for fine analyses essential, in order to be able to comply with specified limit and tolerance values.

-

Processing cocoa beans in the laboratory

The most important products which we as consumers come in contact with are cocoa beverages and chocolate. The most important characteristic trait for us is the taste. But before they become chocolate, the cocoa beans have to be roasted, peeled and cracked open.

-

Sample preparation for refuse derived fuels

Plastic, wood and shredded waste, are in times of rising crude oil prices very interesting additions to the classic fuels. Especially in the cement industry, the energy rich fractions from conditioning processes are readily burned along. Important here is the analytical evaluation of the materials.

-

Analysis of lead in toys

Important and always current is the analysis of lead in toys for children. Details about the effective sample comminution.

-

Phytopharmaceuticals, Traditional Chinese Medicine, Natural Cosmetics

Scientists, pharmacists and doctors are increasingly, systematically and more extensively occupied with the components of medical plants. These always have to be analysed.

-