Further Ball Mills

FURTHER PRODUCT GROUPS

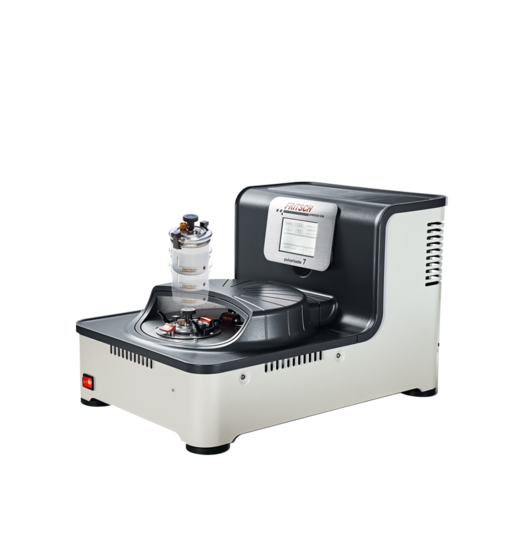

Mini-Mill

PULVERISETTE 23

-

OVERVIEW

The smallest instrument for smallest quantities

The ultra-compact FRITSCH Mini-Mill is ideal for fine comminution of smallest quantities of medium-hard, brittle and moist samples – wet, dry or cryogenic. Its special spherical grinding bowl ensures a much better performance in grinding, mixing and homogenizing compared with similar models. With a footprint of just 20 x 30 cm and a weight of 7 kg it easily fits anywhere; it’s smart, user-friendly, inexpensive and convinces with impressive results, small, fast, effective.

-

WORKING PRINCIPLE

Impact and friction

The FRITSCH Mini-Mill PULVERISETTE 23 grinds the sample through impact and friction between grinding balls and the inside wall of the grinding bowl. For this, the grinding bowl performs vertically oscillating movements with 900 – 3,000 oscillations per minute at 9 mm amplitude.

In contrast to similar mills, a clearly better degree of efficiency is achieved due to the spherical-shaped inside of the grinding bowl, which is perfectly adapted to the communition principle. -

FEATURES

- Fast, reproducible comminution

- Extremely compelling in price and in performance

- Convenient grinding bowl mount with plug-style closures practical and quick clamping system

- Grinding bowl oscillations: 900 - 3,000 oscillations/min at 9 mm amplitude

- Regulated oscillation frequency (15 – 50 Hz)

- Small grinding bowl volumes for smallest sample quantities 0.1 ml – 5 ml

- Low contact surface area with grinding elements

- Operating panel with integrated, easy-to-clean glass keyboard

- Extensive accessories for simplifying your daily work

-

EFFECTIVE GRINDING

Unmatched effectiveness with spherical grinding bowls

Available only from FRITSCH: In Special consideration of the ball mill grinding concept, we developed for the PULVERISETTE 23 a grinding bowl with interior walls that are spherical instead of cylindrical. Your advantage: Unmatched grinding performance with a significantly improved grinding effect, much easier recovery and simpler cleaning.

Especially practical: The spherical grinding bowls of the PULVERISETTE 23 are assembled simply and quickly, just twist and turn! -

BIOTECHNOLOGICAL APPLICATION

PTFE bowl

The 5 and 30 ml PTFE grinding bowls are especially suited for using the FRITSCH PULVERISETTE 23 in biotechnology applications. For example, it is possible to break up fungus or yeast cells, deep frozen tissue and cells in only a few minutes with this special plastic bowl and the corresponding grinding balls. It is also possible to pre-cool the entire bowl in liquid nitrogen.

-

EQUIPMENT / ACCESSORIES

Grinding bowl and grinding balls

The Mini-Mill PULVERISETTE 23 operates with a grinding bowl and grinding balls. To avoid undesired contamination of the sample through abrasion, we offer a selection of 3 different materials. Normally, grinding bowls and grinding balls of the same material are used. Grinding bowls and grinding balls made of zirconium oxide for absolute metal-free grinding are also offered.

-

Applications / Solutions

-

Medium-hard to hard materials with edge lengths up to 95 mm can be pre-crushed with the FRITSCH Jaw Crusher PULVERISETTE 1 so an additional fine comminution with many FRITSCH mills is possible.

-

Quality and process assurance of clean room concepts

In the food industry the trends of the future are „Healthy Nutrition and „Convenience Products". The markets are shaped by wellness and health, as well as fitness oriented consumers which demand natural products in convenient packaging.

-

Detection of azoic dye in clothing and fibre material

Our clothing is labelled by producers informing consumers of what material the article is made of. Very often the clothing contains particularly colour intensive sample elements in which their fibres can not be clearly identified. Here it is important for the method of preparation to determine the type of fibre respectively to confirm it.

-

Drug testing via hair analysis

In order to proof the consumption of drugs (cocaine, cannabis products, amphetamines) even after long periods of time, hair is frequently analyzed.

-